Machine Travels: X x Y x Z in (mm)

25.6 x 17.7 x 13.8 (650 x 450 x 350)

Maximum Workpiece Size: W x D x H in (mm)

41.3 x 29.9 x 13.8 (1050 x 760 x 350)

Max Dielectric Fluid Level: in (mm)

15.7 (400)

Power Supply (Option) / Peak Current

FP80V (80 Peak) FP120V (120 Peak)

Internal Worktank Dimensions W x D x H in (mm)

43.3 x 31.9 x 17.7 (1100 x 810 x 450)

Worktank / Door Type

3-Sided Drop Ttank

Max. Workpiece Weight: lb (kg)

4400 (2000)

Table Dimensions W x D: in (mm)

33.4 x 23.6 (850 x 600)

Max. Electrode Weight: lb (kg)

440 (200)

Table to Platen Distance Min ~ Max: in (mm)

16.7 ~ 30.5 (425 ~ 775)

Table to C-Axis Chuck Distance Min ~ Max: in (mm)

12.5 ~ 23.6 (317 ~ 667) EROWA ITS Chuck

Table to C-Axis Chuck Distance Min ~ Max: in (mm)

11.8 ~ 25.6 (300 ~ 650) 3R MACRO Chuck

Minimum Command Unit / Resolution: in (mm)

.00001 / .000002 (.0001 / .00005)

Rapid Travel Speed: in/min. (mm/min.)

78.7 (2000)

High-Speed Jump Maximum: in/min. (m/min.)

393 (10)

Filters / Type

3 pc. / Paper Cartridge

Filter Tank Capacity: gal (L)

157 (595)

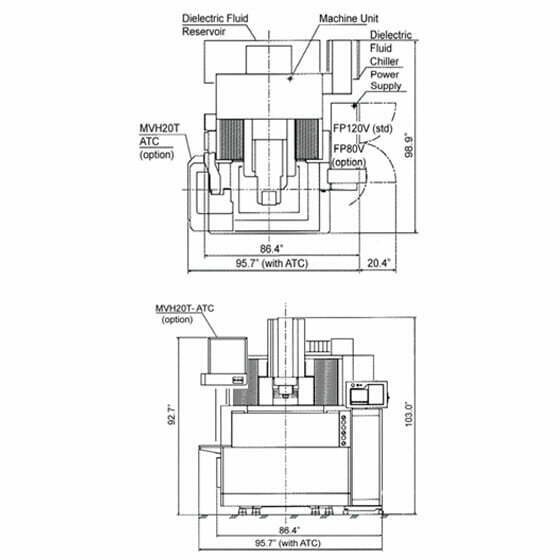

Machine System Dimensions W x D: in (mm)

86.4 x 98.9 (2195 x 2512)

Machine Installed Height: in (mm)

103 (2615)

Machine System Weight: lb (kg)

11,904 (5400)

C-Axis Min. Indexing Angle / Drive Unit

.001º / .001º

Fluid Temp. Control

Chiller Standard

Optional Internal Spindle RPM Range

1 ~ 1500

Automatic Tool Changer Options

MVH 20 / 40

Power Requirements [KVA]

200/220 VAC +/- 5% [16.5]

Compressed Air Requirements

2.7 cu.ft./min @ 90-100 psi