Machine Travels: X x Y x Z in (mm)

15.7 x 11.8 x 11.8 (400 x 300 x 300)

Max Dielectric Fluid Level: in (mm)

3.1 ~ 15.7 (79 ~ 400)

Power Supply (Option) / Peak Current

80

Internal Worktank Dimensions W x D x H in (mm)

35.4 x 27.5 x 17.7 (900 x 700 x

Max. Workpiece Weight: lb (kg)

2200 (998)

Table Dimensions W x D: in (mm)

27.6 x 19.7 (702 x 500)

Max. Electrode Weight: lb (kg)

110 (50)

Table to Platen Distance Min ~ Max: in (mm)

7.9 ~ 19.7 (200 ~ 500)

Table to C-Axis Chuck Distance Min ~ Max: in (mm)

7.9 ~ 19.7 (200 ~ 500) EROWA ITS Chuck

Table to C-Axis Chuck Distance Min ~ Max: in (mm)

7.2 ~ 19.0 (183 ~ 483) 3R MACRO Chuck

Filters / Type

Paper Cartridge (2 pc)

Machine System Weight: lb (kg)

7716 (3500)

C-Axis Min. Indexing Angle / Drive Unit

0.001 ̊/ 0.001 ̊

Fluid Temp. Control

Chiller

Table to Platen Distance in (mm)

7.9 - 19.7 (201 - 500)

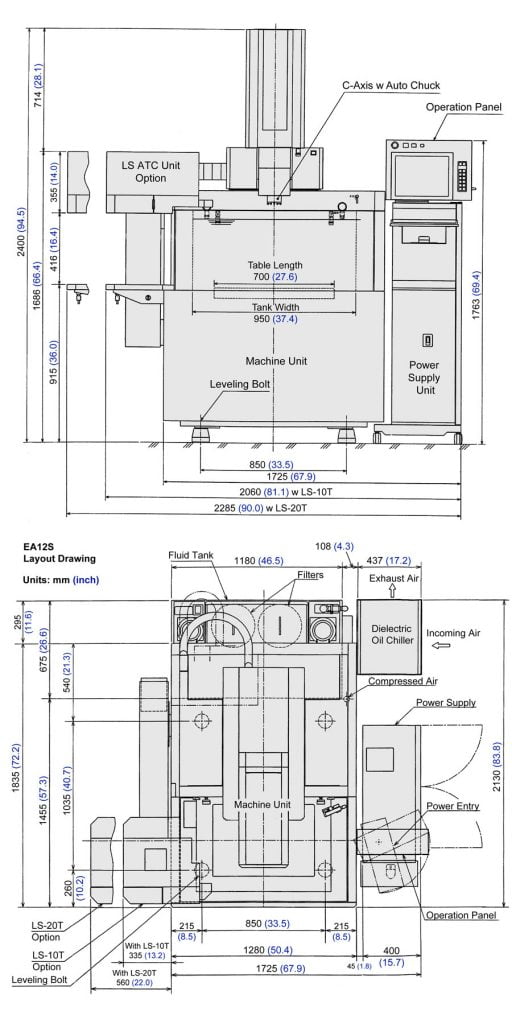

Machine Unit Dimensions W x D x H in (mm)

67.9 x 83.9 x 94.5 (1725 x 2132 x 2400)

Control Unit Program Support Function

E.S.P.E.R Advance

Control Unit Machining Function

Fuzzy Pro 3 Plus

Control Unit Graphic Display Function

15" TFT color LCD

Control Unit CPU/type

64-bit / PC

Dielectric Fluid System Reservoir Capacity gal (L)

124 (470)

Installation Dimensios W x D in (mm)

89.9 x 83.8 (2281 x 2130) wATC

Floor Space Requirement sq. ft

52.3

C-Axis Max. Electrode Weight lb (kg)

11 (5)