Menu

WP_Post Object

(

[ID] => 11332

[post_author] => 40

[post_date] => 2023-08-01 11:09:42

[post_date_gmt] => 2023-08-01 15:09:42

[post_content] => Main Features of Rolled Steel Laser Cutter

1. Stepless Speed Regulation

The support roller is driven to rotate by the geared motor through the sprocket strip, and always keeps the plate between the uncoiling and feeding in the suspended state, and the speed reaches 393″/min, in order to achieve the preparation for stress relief. And the load-bearing capacity of the single-support uncoiler is 22000 lbs

2. Ultra-Precision Correction Technology

A special lead screw nut is used to drive the correcting roller to install the sliding block, so that the correcting tube wheel can straighten the plate, realize the guiding positioning of the plate, prevent the plate from being scratched during the movement process, and accurately position the plate without laser edge seeking, saving the time of plate cutting.

3. Extremely Fast Stress Relief Technology

After the coil is uncoiled, while the flat material is leveled by the leveling machine, the internal stress of the plate can be released in advance, making the plate smoother, and the excellent laser cutting experience and efficiency have never been obtained.

Application

This product is mainly used in the cutting field of thin stainless steel materials and industries where the thickness of the product is relatively single. For example, automotive sheet metal parts, aluminum veneer, electrical cabinets, metal door industry, kitchen utensils industry, equipment sheet metal, etc.

Coil Fed Fiber Laser Cutting Machine SF1503CH

[post_title] => SF1503CH

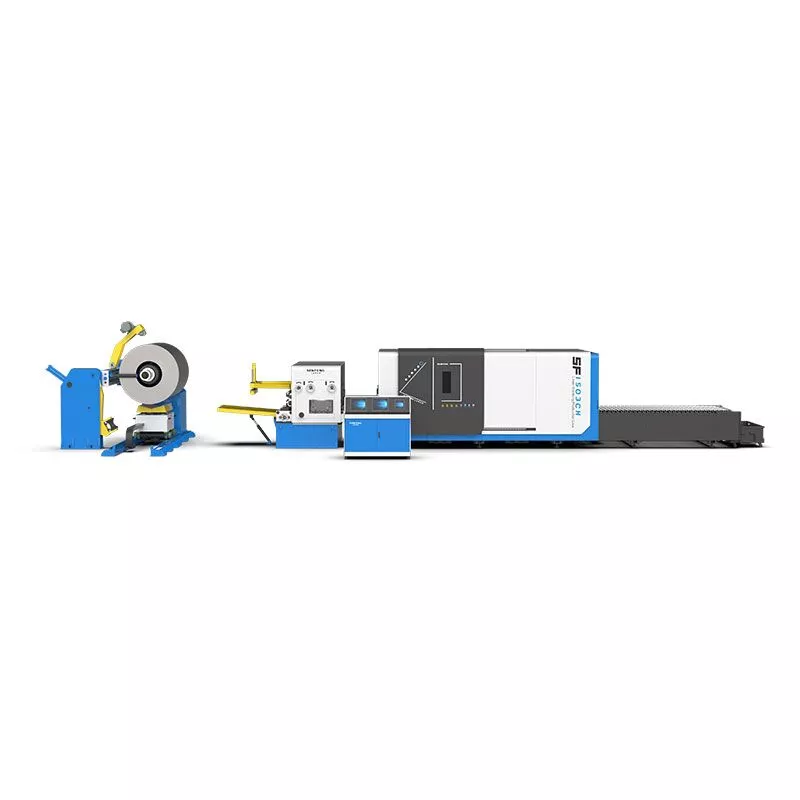

[post_excerpt] => The SF1503CH rolled steel cutting machine from Senfeng is composed of a feeding trolley, a single support uncoiler, auxiliary support, a feeding mechanism, a leveling feeder, a sheet metal positioning and correction device, a laser cutting unit, and an electronic control system. The automatic design of the whole process, which is from loading-uncoiling-leveling-cutting saves labor, realizes the net cutting of coil materials, and improves the utilization of sheet materials.

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => sf1503ch

[to_ping] =>

[pinged] =>

[post_modified] => 2023-08-02 09:17:27

[post_modified_gmt] => 2023-08-02 13:17:27

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://spark-co.com/machines/%machinecategory%/sf1503ch/

[menu_order] => 9

[post_type] => machine

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

Array

(

[0] => Laser Cutting

)

The SF1503CH rolled steel cutting machine from Senfeng is composed of a feeding trolley, a single support uncoiler, auxiliary support, a feeding mechanism, a leveling feeder, a sheet metal positioning and correction device, a laser cutting unit, and an electronic control system. The automatic design of the whole process, which is from loading-uncoiling-leveling-cutting saves labor, realizes the net cutting of coil materials, and improves the utilization of sheet materials.

Main Features of Rolled Steel Laser Cutter

1. Stepless Speed Regulation

The support roller is driven to rotate by the geared motor through the sprocket strip, and always keeps the plate between the uncoiling and feeding in the suspended state, and the speed reaches 393″/min, in order to achieve the preparation for stress relief. And the load-bearing capacity of the single-support uncoiler is 22000 lbs

2. Ultra-Precision Correction Technology

A special lead screw nut is used to drive the correcting roller to install the sliding block, so that the correcting tube wheel can straighten the plate, realize the guiding positioning of the plate, prevent the plate from being scratched during the movement process, and accurately position the plate without laser edge seeking, saving the time of plate cutting.

3. Extremely Fast Stress Relief Technology

After the coil is uncoiled, while the flat material is leveled by the leveling machine, the internal stress of the plate can be released in advance, making the plate smoother, and the excellent laser cutting experience and efficiency have never been obtained.

Application

This product is mainly used in the cutting field of thin stainless steel materials and industries where the thickness of the product is relatively single. For example, automotive sheet metal parts, aluminum veneer, electrical cabinets, metal door industry, kitchen utensils industry, equipment sheet metal, etc.