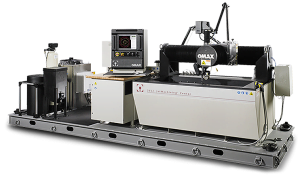

The Small format waterjet cutting OMAX® 2652 JetMachining Center is a mid-sized cantilever-style machine with the power and precision you need in a size to fit into any shop, big or small.

Offering the fastest cutting speeds and best precision compared to any competitive abrasive waterjet in the industry, this mighty mid-sized abrasive waterjet machine features robust and accurate design for tight tolerance cutting and reliable operation.

Its compact format takes up less floor space while getting the job done thanks to the precision X-Y axis rigidly mounted to the cutting table, preloaded linear bearings and precision ball screws, and a drive system that is sealed against water, dirt and grit. With no tool changes and minimal fixturing, you save valuable time on setup and maintenance.

The Small format waterjet cutting machine OMAX 2652 boats a cutting tolerance of ±0.001″ (±0.025 mm), a maximum speed of 180 inches/minute (4,572 mm/min) and a completely sealed and protected ball-screw drive system, making it the ideal choice for shops cutting projects with smaller dimensions but needing high precision.

OMAX waterjets boast the lowest electrical consumption in the industry and use substantially less cooling water than inefficient hydraulic intensifier pumps.

EnduroMAX® direct drive pump technology delivers the highest nozzle horsepower in the industry for faster cutting with operating efficiencies of up to 85% and this, with over 1,000 hours between maintenance for increased uptime.

Standard features include a high-quality, integrated OMAX MAXJET® 5i Nozzle for more accurate and consistent jet alignment, which ultimately prolongs mixing tube life and delivers better quality cuts over the nozzle assembly life. Work clean, safe and quiet with the Rapid Water Level Control for submerged cutting below 80 dBA.

Optional accessories such as the bulk abrasive delivery system, scissor-style hard plumbing for added safety and reliability, tilt-a-jet taper eliminating abrasive jet cutting head and variable speed solids removal system (VS-SRS) expand your jetmachining capabilities and dramatically improve production.

Spark & Co. has been a distributor of OMAX waterjet cutting systems (PROTOMAX®, GLOBALMAX®, MAXIEM® and OMAX® series) for over a decade. No one is better equipped to meet your needs in waterjet, Laser (2D laser, Tube Laser, Shaping and Finishing.

For more information : https://www.omax.com/omax-waterjet/2652

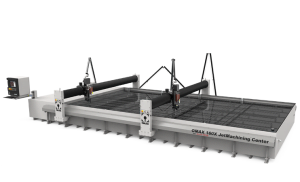

MAXIEM 1530

MAXIEM 1530 OMAX 2652

OMAX 2652 OMAX 55100

OMAX 55100 Maxiem 1515

Maxiem 1515 Protomax

Protomax