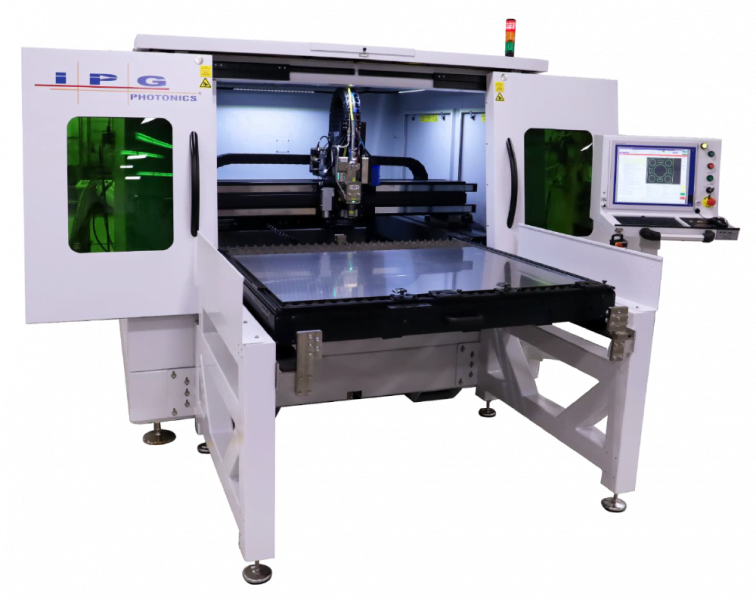

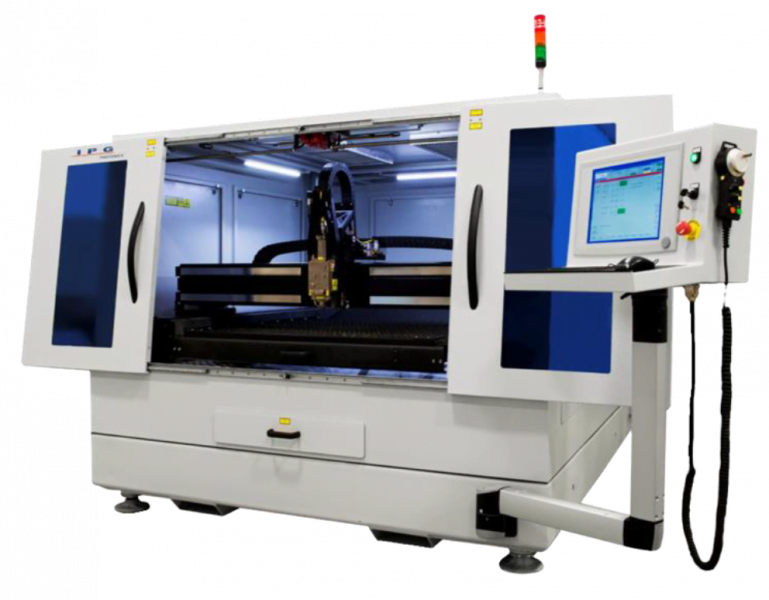

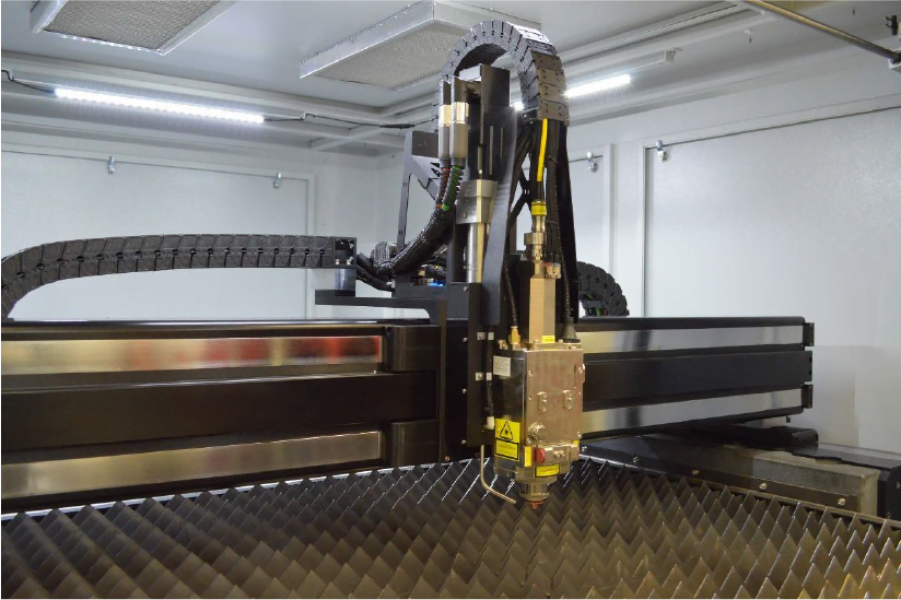

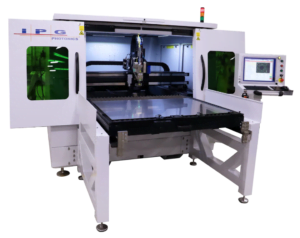

The IPG LaserCube is available in a power range of 500–6000 watts. Our customers use a wide range of materials, including stainless steel, aluminum, titanium, composites, copper, brass and even silver. The LaserCube is very precise and uses linear motors, with no ball screws or rack and pinions that can wear out. Customers that currently have laser systems tell me they use the LaserCube for all their high-precision, critically-sized parts. IPG is the benchmark for fibre laser quality. We manufacture this equipment in an environment where excellence is the order of the day.

The LaserCube is entirely manufactured by IPG. We also supply fibre resonators to Mitsubishi, Mazak, Bystronics, HK, Cincinnati, and practically everyone else except Trumpf. The resonator is, of course, the essential part of the laser. IPG manufactures this key component, as well as the rest of the machine.

The machines range in price from $255,000 to $365,000, depending on resonator power and other options. Our 2-km laser includes the Power Pierce, which drills at 4 kW and cuts at 2 kW. A tremendous advantage for cleaner, faster drilling. Since IPG manufactures the entire machine, it can sell the resonator part at the same price as if sold to the OEM. You therefore get the power you need at a great price. For example, a 4 Kw LaserCube costs only $295,000, a special price that includes a 2-year usage warranty with no hour limits; the machine itself comes with a 1-year warranty.

LaserCubes can be financed over 60 to 84 months with a single down payment and a one-page credit application. Eligibility requirements are very simple. Chuck Stump is the person in charge at IPG. He’s easy to work with, without any hassle.

Attached please find information about the IPG LaserCube. Delivery takes approximately 60 to 90 days. The machines are manufactured near Boston, Massachusetts, USA. The purchasing process includes an invitation from IPG to come to the production plant to see your machine and sign for it before it’s shipped. Customers really appreciate this opportunity because it’s always interesting to see where a machine is made. You also receive additional training to learn everything about the machine you’re getting before it ships.

The IPG LaserCube comes with an optional vision alignment system. This system is relatively inexpensive (approx. $10,000) and lets you process combinations of parts. For example, in the case of sheets of parts that first go through the turret in forming applications like those for louvres or milling cutters, the LaserCube can make holes or special cuts or cut the outer shape. The LaserCube uses its vision alignment system to detect a hole or other feature in the parts coming out of the turret and then directs the cutting program. The system is very accurate. You can also machine laser parts the same way. It’s sometimes easier to machine and thread a hole on the machining centre, then bring a plate of parts to the LaserCube and cut the outer shape. The system can also separate preprinted metal plates used to make nameplates. The system can be ordered new or refurbished. Listen to the podcast on vision alignment and machine accuracy.

LaserCube podcast at https://lasercube.podbean.com

For more information, check out:

https://lasersystems.ipgphotonics.com/Products/lasercube/lasercube

MAXIEM 1530

MAXIEM 1530 OMAX 2652

OMAX 2652 OMAX 55100

OMAX 55100 Maxiem 1515

Maxiem 1515 Protomax

Protomax