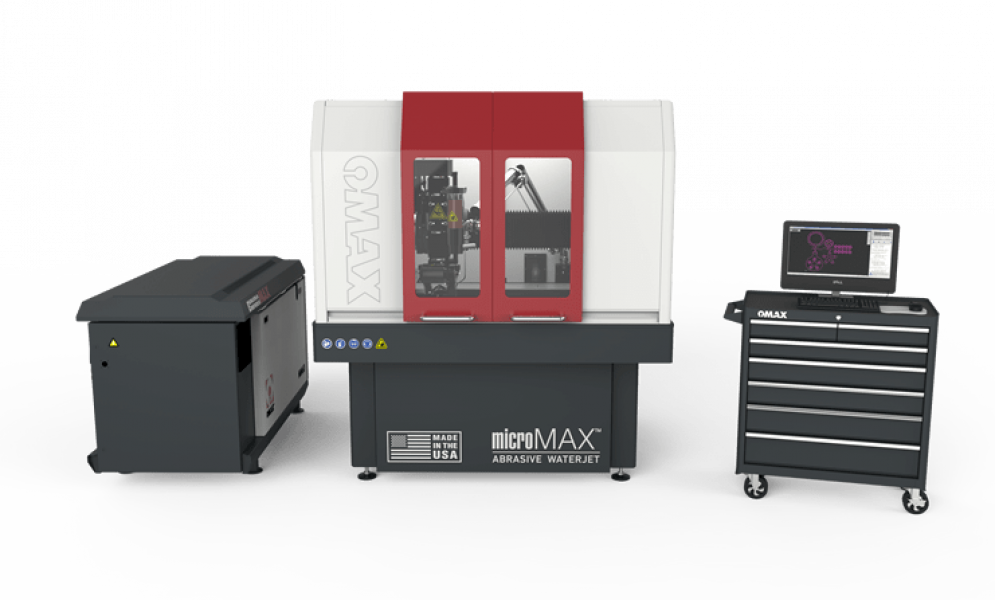

The ultra precision waterjet MICROMAX® JetMachining Center is the ideal solution for ultra-precision abrasive waterjet machining.

Utilizing advanced high-precision optical linear encoders, innovative vibration isolation, and proven software control systems, the ultra precision waterjet MICROMAX JetMachining Center is capable of a positioning accuracy of less than five microns while retaining all the advantages of abrasive waterjet machining.

The ultra precision waterjet MICROMAX machines a wide range of materials with high accuracy, handling hardened steel as easily as annealed steel and easily cutting non-conductive and reflective materials. It machines stainless steel, titanium, carbon fiber, PEEK, glass, nitinol, graphite, copper, composites, laminates, and more, with high precision, smooth finishing and no heat-affected zones or mechanical stresses, for either prototyping or production.

Small but mighty, one of the many advantages of the ultra precision waterjet MICROMAX is its small, efficient footprint for minimal floorspace utilization. Its highly rigid structure with low mass bridges and carriages plus vibration isolation of table and gantries greatly reduces vibration and increases accuracy. What’s more, all components have matched thermal expansion to keep performance smooth and stable.

Equipped with a host of standard features, this powerful little abrasive waterjet is the one you want in your shop: the OMAX 7/15 Mini MAXJET® 5 Nozzle for finer precision cutting capability with a 0.007" (0.1778 mm) orifice and a 0.015" (0.381 mm) mixing tube combination, the Tilt-A-Jet® taper eliminating abrasive jet cutting head and a Rapid Water Level Control for cleaner, safer, and quieter submerged cutting.

The MICROMAX offers all this, plus a revolutionary patent-pending process for fine abrasive feed rate, advanced pressure controls for piercing delicate materials and a full enclosure with environmental controls that provides quiet, safe and clean operation below 80db.

Spark & Co. has been a distributor of OMAX waterjet cutting systems (PROTOMAX®, GLOBALMAX®, MAXIEM® and OMAX® series) for over a decade. No one is better equipped to meet your needs in waterjet, Laser (2D laser, Tube Laser, Shaping and Finishing.

For more information : https://www.omax.com/omax-waterjet/micromax

MAXIEM 1530

MAXIEM 1530 OMAX 2652

OMAX 2652 OMAX 55100

OMAX 55100 Maxiem 1515

Maxiem 1515 Protomax

Protomax