OMAX MOBILE JMC

Menu

| Footprint * – (L x W) | 18’ 9” x 9’ 2” |

| Height ** | 9’ 7” |

| Weight (tank empty) | 6,200 lb |

| X-Y Cutting Envelope *** | 10’ 6” x 5’ 2” |

| Z-Axis Travel *** | 8” |

| Table Size – (L x W) | 12’ 0” x 6’ 5” |

| Speed | 180 in/min |

| Linear Positional Accuracy | ±0.0010" |

| Repeatability | ±0.0010" |

| Ballbar Circularity | ±0.0025" |

DESCRIPTION

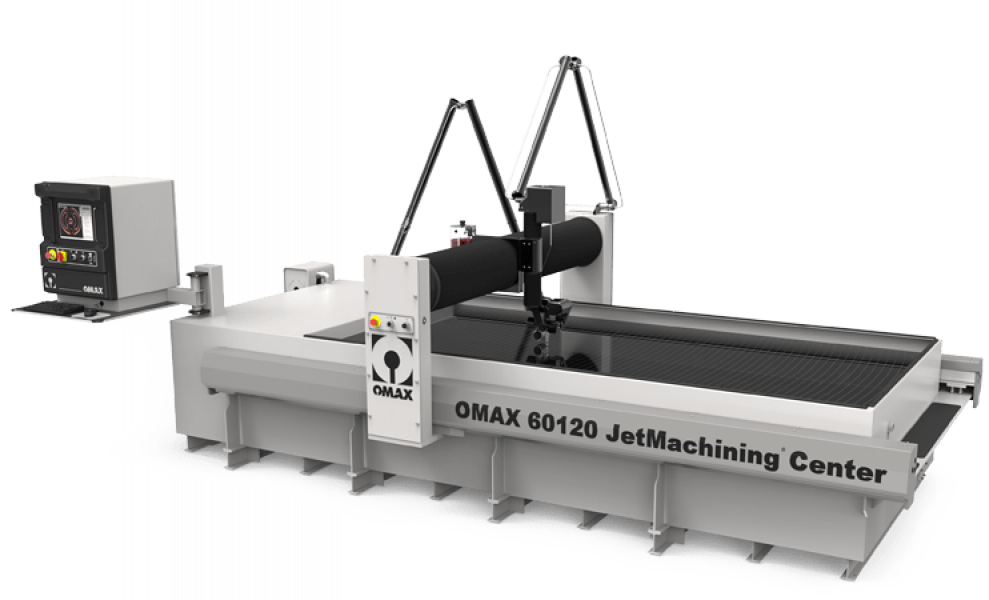

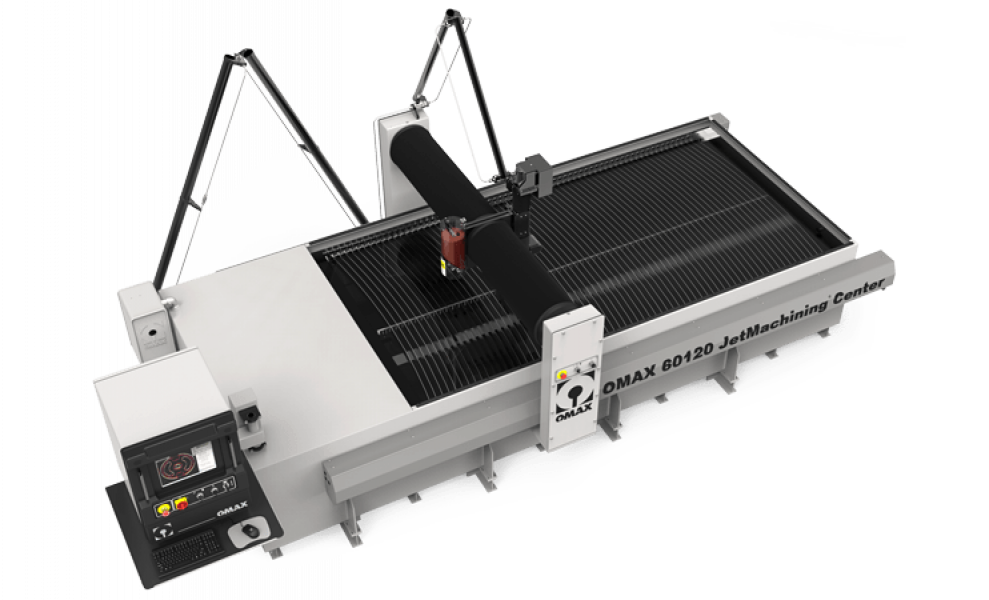

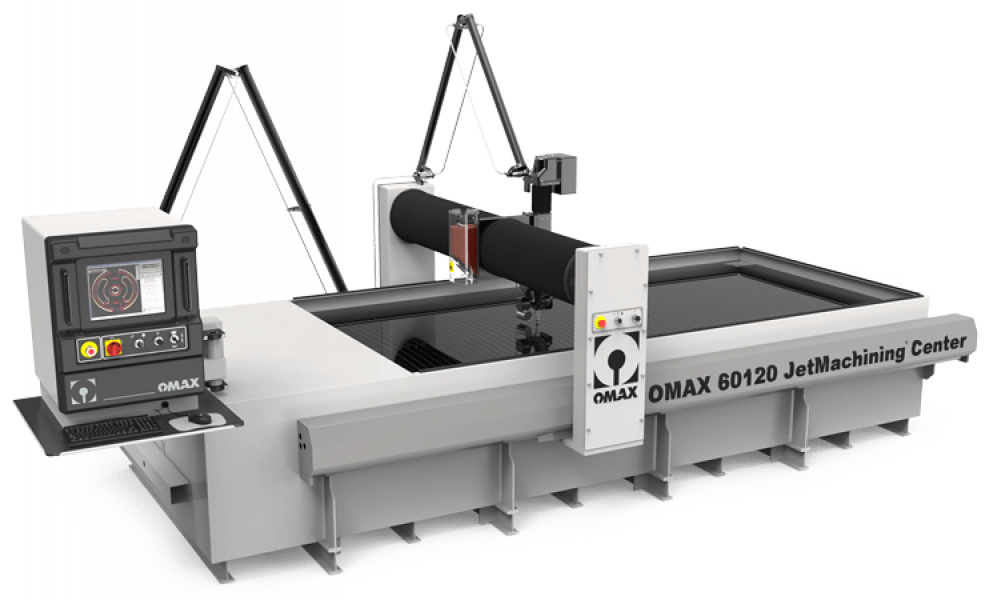

The Omax waterjet 60120 JetMachining Center may be the smallest of our bridge-style waterjet machines, but don’t let its size fool you: with a table big enough to handle larger stock, this small but mighty abrasive waterjet cutS more for less.

If your shop needs unobstructed material loading, the bridge-style Y-axis is the answer. The Omax waterjet 60120 rapidly and precisely gets the job done, maximizing both machine time and profit margins.

The Omax waterjet 60120 abrasive waterjet system can easily machine almost any material and thicknesses, from steel and titanium to carbon fiber, composites, glass, and more. With an X-Y cutting envelope of 10’ 6” x 5’ 2” (3,200mm x 1,575mm) a maximum cutting speed of 180 inches per minute (4,572 mm/min) and a linear positioning accuracy of +0.0010” (±0.0254 mm), this bridge-style waterjet cutter maximizes profitability through operational efficiency.The Omax waterjet 60120 abrasive waterjet machine system comes standard with a host of high-performance features, including a 600lb-bulk abrasive delivery system that transports garnet from the assembly's large hopper into the Z-Axis zero-downtime hopper and a rapid water level control for cleaner, safer, and quieter submerged cutting below 80 dBA.

OMAX’s patent-pending IntelliTRAX® traction drive, an industry first high-precision linear drive motion control system designed specifically for abrasive waterjets, inside the X-Y axis beams is fully enclosed inside coated steel covers for greater durability and reduced machine maintenance. The system incorporates a magnetic linear encoder and an electronic drive control for precise positioning.

Thanks to its highly efficient EndurMAX® direct drive pump, programmable motorized Z-axis and durable diamond-integrated MAXJET® 5i Nozzle, the OMAX 60120 waterjet cutter belts out extreme nozzle horsepower while saving on energy costs.

This reliable waterjet machine boasts the lowest electrical consumption in the industry, offering up to 85% operating efficiency for faster, more efficient cutting while using substantially less cooling water than inefficient hydraulic intensifier pumps.

This robust system requires little maintenance and is as easy to use as conventional machine tools.

Spark & Co. has been a distributor of OMAX waterjet cutting systems (PROTOMAX®, GLOBALMAX®, MAXIEM® and OMAX® series) for over a decade. No one is better equipped to meet your needs in waterjet, Laser (2D laser, Tube Laser, Shaping and Finishing.

For more information : https://www.omax.com/omax-waterjet/60120

Specifications