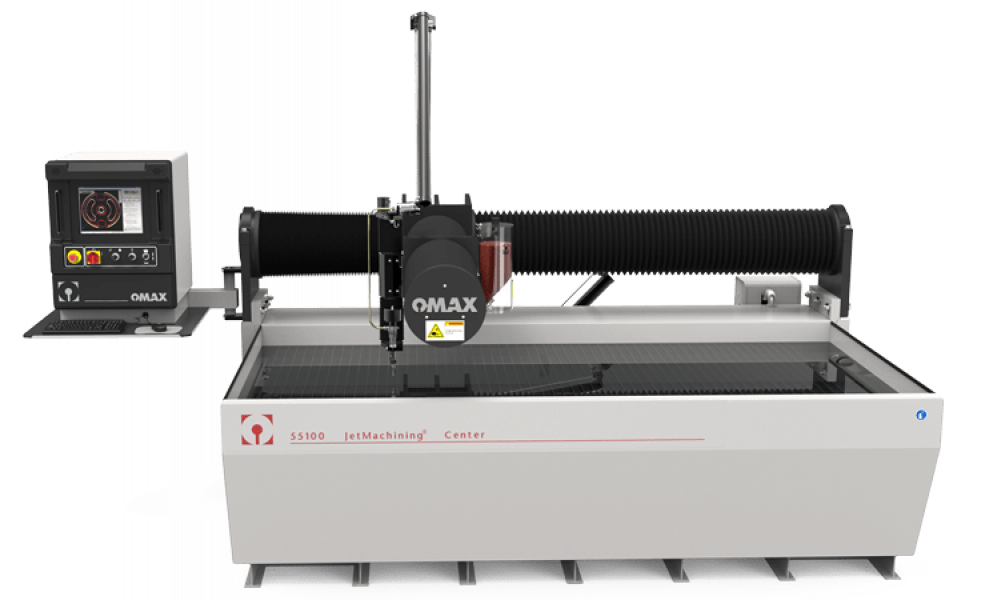

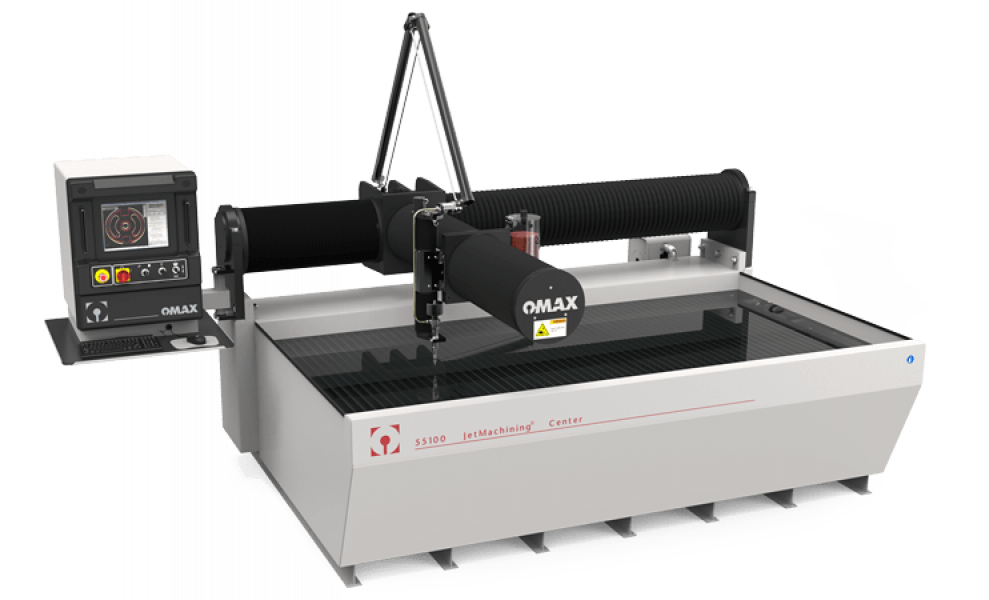

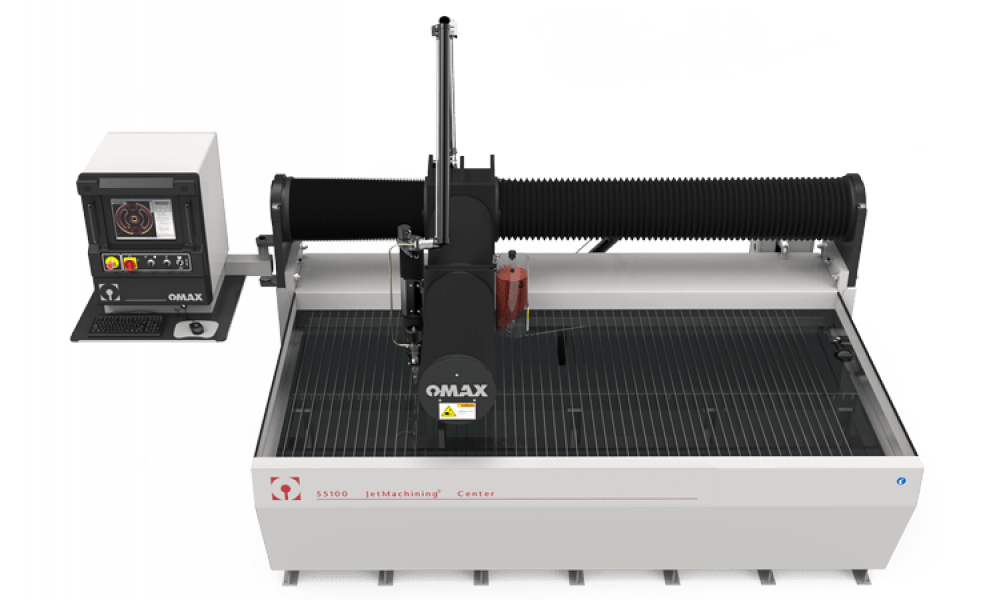

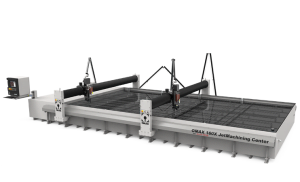

The largest cantilever-style machine in the series, the Omax Waterjet 55100 JetMachining Center is the industry standard workhorse for high-speed precision machining.

The Omax Waterjet 55100 JetMachining Center delivers precisely accurate, multi-axis parts quickly and consistently in almost any material, maximizing machining throughput. Built tough to handle big jobs in a demanding manufacturing environment, it can easily machine almost any material and thicknesses, from steel and titanium to carbon fiber, composites, glass, and more.

With an X-Y cutting envelope of 10’ 6” x 5’ 2” (3,200 mm x 1,575 mm) a maximum cutting speed of 180 inches per minute (4,572 mm/min) and a linear positioning accuracy of +0.0010” (±0.0254 mm), this bridge-style waterjet cutter maximizes profitability through operational efficiency.

With a completely sealed and protected ball screw drive system, the OMAX 55100 is a robust and reliable workhorse for shops using larger stock. From prototyping to full-scale manufacturing, the Omax Waterjet 55100 abrasive waterjet can cut materials up to 4’ x 8’ (1.2 m to 2.4 m) quickly and efficiently.

EnduroMAX® direct drive pump technology, a programmable motorized Z-axis and a durable diamond-integrated MAXJET® 5i nozzle deliver the highest nozzle horsepower in the industry for faster cutting with operating efficiencies of up to 85% and this, with over 1,000 hours between maintenance for increased uptime.

Fast and precise IntelliCAM® software offers simple programming that takes DXF or CAD drawings and quickly creates cutting paths, making the 55100 ideal for short-run part production and just-in-time manufacturing.

Standard Intelli-VISOR® System Monitoring helps you keep on top of scheduled maintenance to keep production high and downtime low.

Operator access and safety is another great feature of the OMAX series abrasive waterjets. An eco-friendly “green” system uses only natural garnet abrasive and water in the cutting process. meaning no noxious fumes, liquid or oils are used in, or caused by, the machining process. Standard scissor-style hard plumbing adds another level of safety by using contained high-pressure components, as well as contributes to a smaller footprint, lower maintenance, and higher reliability.

From small job shops to large production facilities, the OMAX 55100 JetMachining Center reduces cutting times and increases profitability.

Spark & Co. has been a distributor of OMAX waterjet cutting systems (PROTOMAX®, GLOBALMAX®, MAXIEM® and OMAX® series) for over a decade. No one is better equipped to meet your needs in waterjet, Laser (2D laser, Tube Laser, Shaping and Finishing.

For more information : https://www.omax.com/omax-waterjet/55100

MAXIEM 1530

MAXIEM 1530 OMAX 2652

OMAX 2652 OMAX 55100

OMAX 55100 Maxiem 1515

Maxiem 1515 Protomax

Protomax