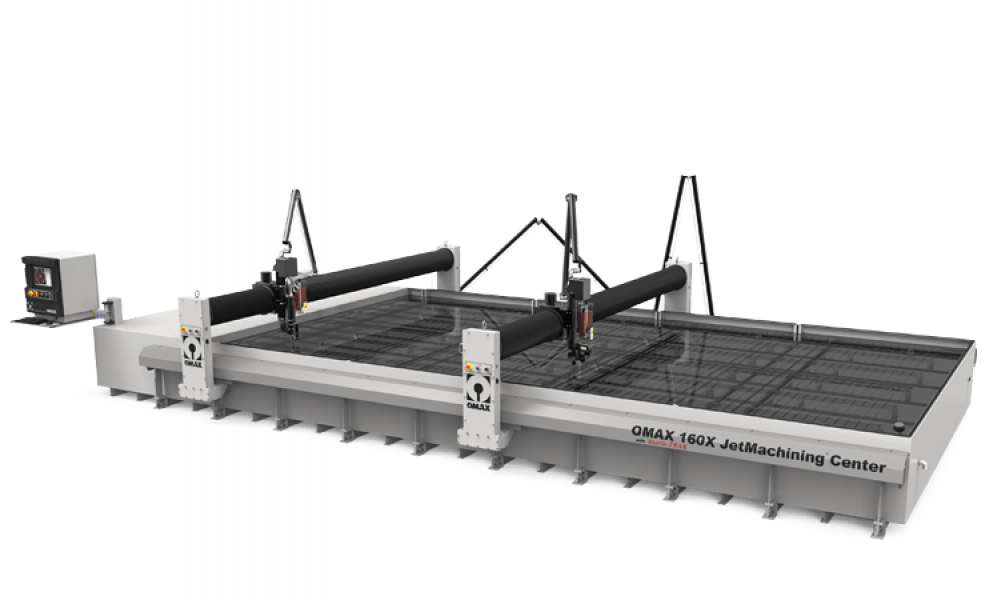

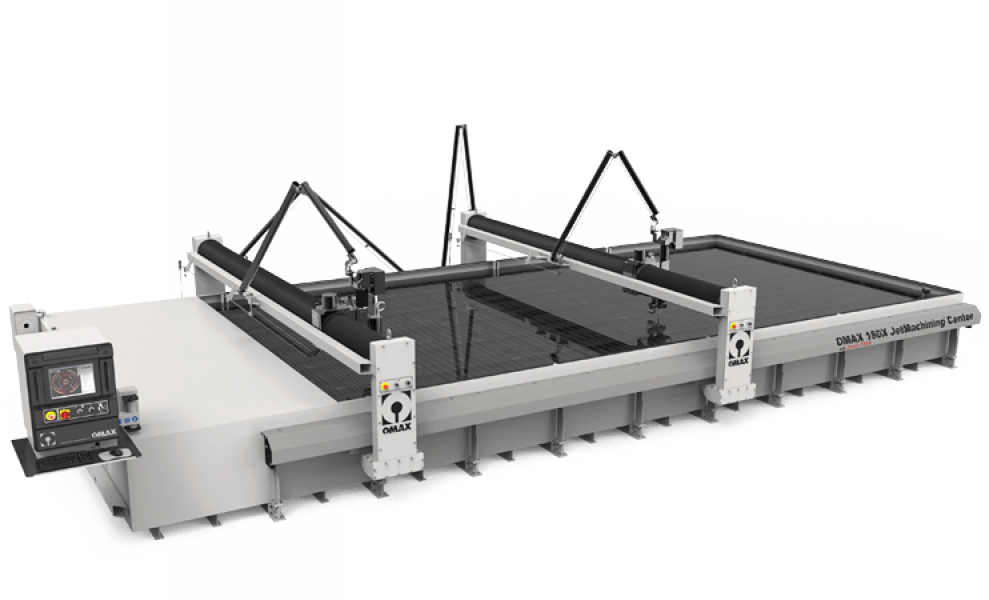

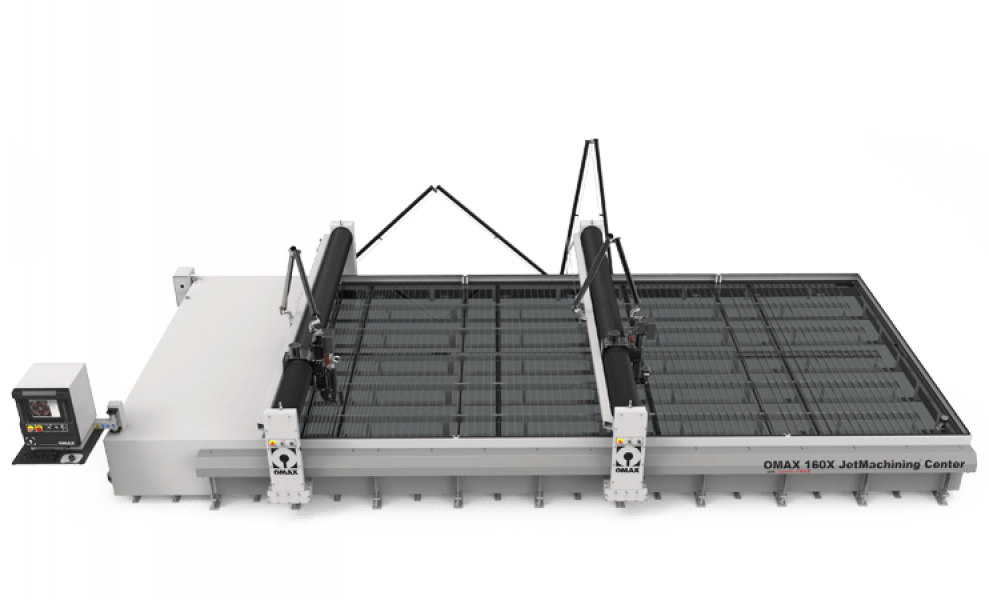

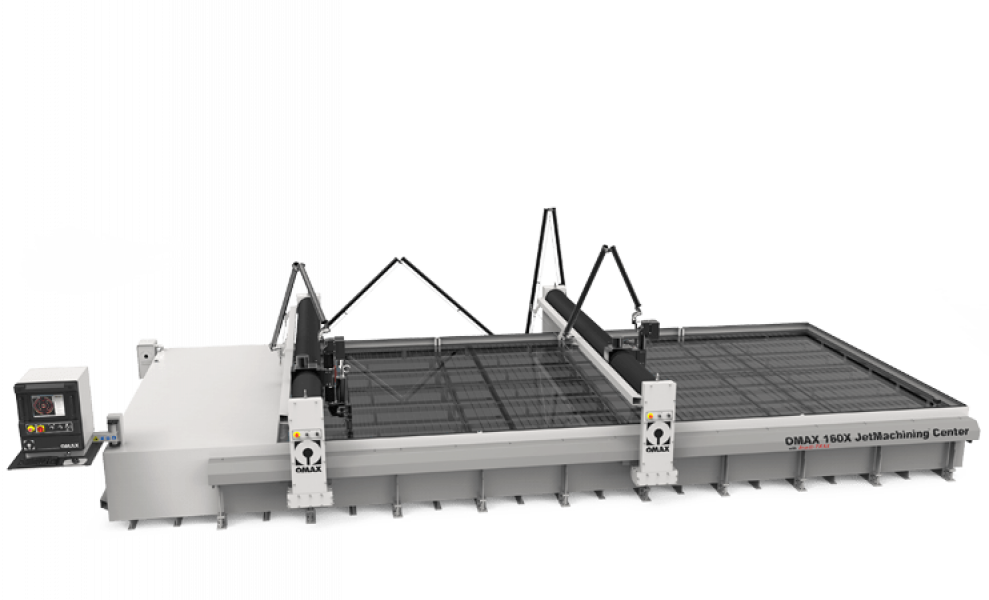

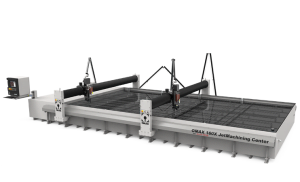

They say that bigger is better, and the largest waterjet Omax 160X series proves it in every way. The largest bridge-style abrasive waterjet machining center in the line, this beast is designed for big jobs, big output and big savings.

Featuring an expansive 26’ 8" x 13’ 4” (8,128 mm x 4,064 mm) cutting area, the largest waterjet Omax 160X cuts at an impressive 350 inches per minute (8,890 mm/min) with a linear positional accuracy of ±0.0010" (±0.0254 mm). Typical of OMAX waterjets, it offers the fastest cutting speeds and best precision compared to any competitive abrasive waterjet in the industry.

An innovative bridge-style waterjet cutter, the 160X is ideal for cutting larger or multiple part projects in a variety of materials and thicknesses, from metals and composites to glass and plastics and more. It employs the innovative patented Intelli-TRAX® linear drive technology designed exclusively for the abrasive waterjet environment, ensuring superior accuracy and high durability for greater productivity and profitability.

Safety and ergonomics are also part and parcel of this high efficiency waterjet. An eco-friendly “green” system uses only natural garnet abrasive and water in the cutting process, meaning no noxious fumes, liquid or oils are used in, or caused by, the machining process. Standard scissor-style hard plumbing adds another level of safety by using contained high-pressure components, as well as contributes to a smaller footprint, lower maintenance, and higher reliability.

Program 2D or 3D tool paths from 3D models at the touch of a button with exclusive IntelliMAX® Software Suite featuring IntelliCAM® programming software and real-world cutting data.

EnduroMAX® direct drive pump technology delivers the highest nozzle horsepower in the industry for faster cutting with operating efficiencies of up to 85% and this, with over 1,000 hours between maintenance for increased uptime.

With innovative accessories such as the DualBRIDGE system, Tilt-A-Jet®, A-Jet®, and Rotary Axis, the 120X Series is a robust and versatile system that provides superior performance to maximize productivity and profitability.

Spark & Co. has been a distributor of OMAX waterjet cutting systems (PROTOMAX®, GLOBALMAX®, MAXIEM® and OMAX® series) for over a decade. No one is better equipped to meet your needs in waterjet, Laser (2D laser, Tube Laser, Shaping and Finishing.

For more information : https://www.omax.com/omax-waterjet/160x-series

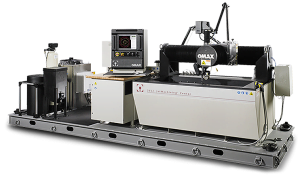

MAXIEM 1530

MAXIEM 1530 OMAX 2652

OMAX 2652 OMAX 55100

OMAX 55100 Maxiem 1515

Maxiem 1515 Protomax

Protomax