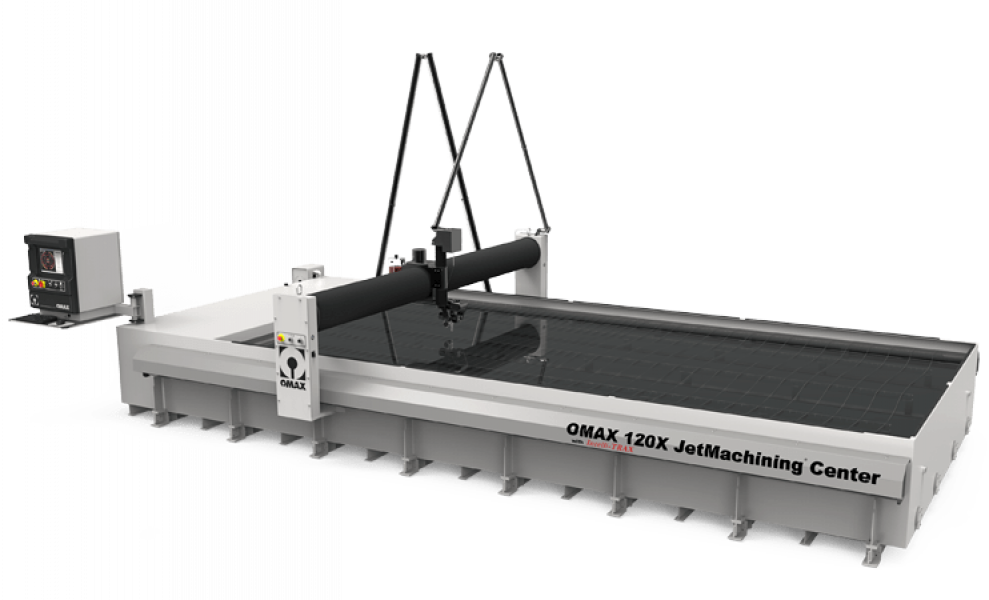

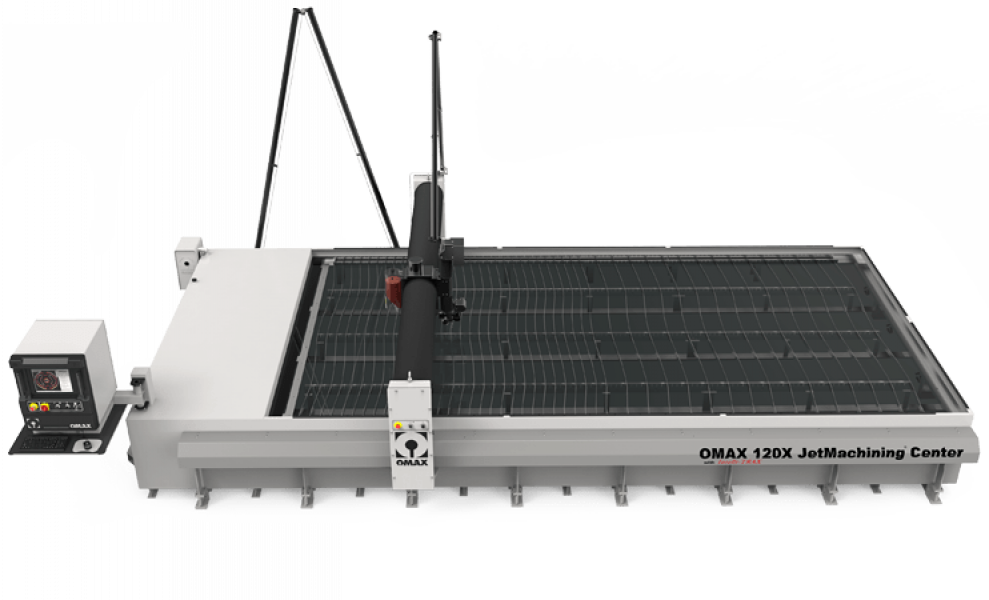

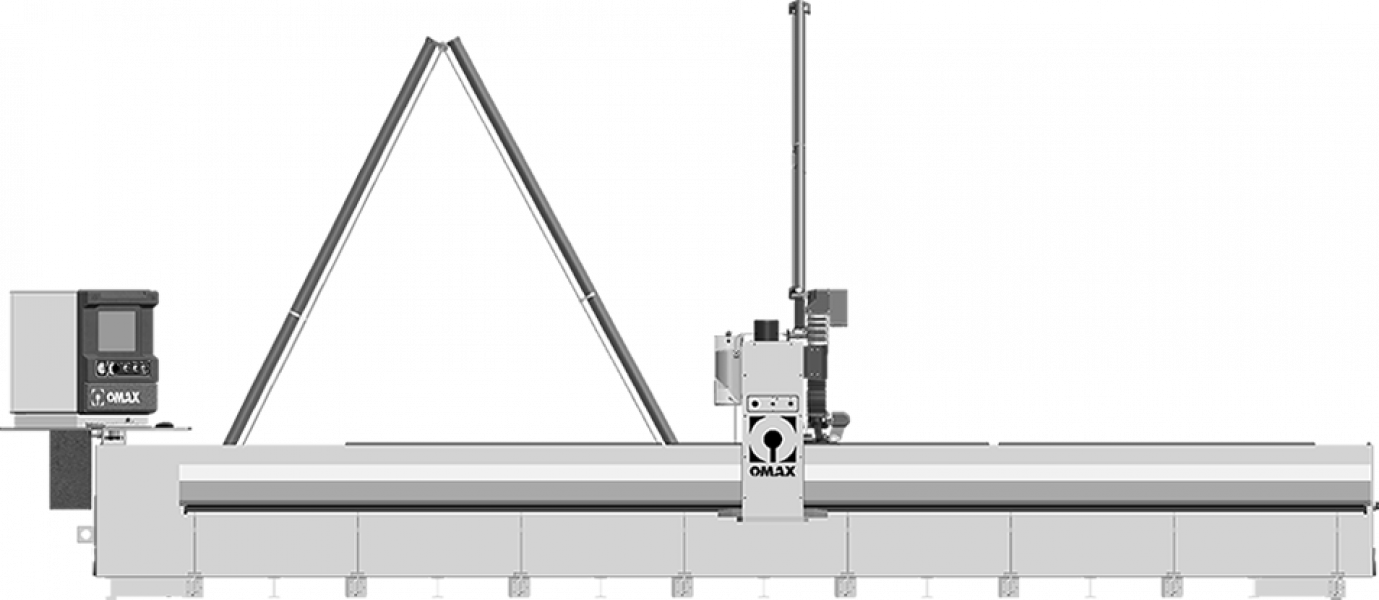

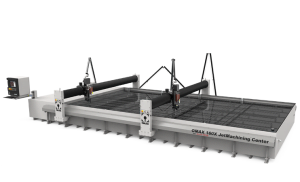

Large format bridge-style Omax Waterjet 120X Cutting Machine Series JetMachining Centers are ideal for full scale production of large or multiple part projects.

With a hefty 20’ x 10’ (6,096 mm x 3,048 mm) cutting area, a maximum cutting speed of 180 inches per minute (4,572 mm/min) and a linear positioning accuracy of +0.0010” (±0.0254 mm), this impressive bridge-style waterjet machine cranks out part after part, while saving you money on operating costs.

The Omax waterjet 120X cutting machine, cut fast and clean thanks to a programmable, motorized Z-Axis with a precision, diamond-integrated OMAX MAXJET®5i nozzle Assembly, leaving behind satin-smooth edges with little to no secondary operations.

Available in a variety of machine lengths, each model features the advanced patented high-precision Intelli-TRAX® linear drive technology designed exclusively for the abrasive waterjet environment.

EnduroMAX® direct drive pump technology delivers the highest nozzle horsepower in the industry for faster cutting with operating efficiencies of up to 85% and this, with over 1,000 hours between maintenance for increased uptime.

Operator access and safety is another great feature of the OMAX series abrasive waterjets. An eco-friendly “green” system uses only natural garnet abrasive and water in the cutting process, meaning no noxious fumes, liquid or oils are used in, or caused by, the machining process. Standard scissor-style hard plumbing adds another level of safety by using contained high-pressure components, as well as contributes to a smaller footprint, lower maintenance, and higher reliability.

Program 2D or 3D tool paths from 3D models at the touch of a button with exclusive IntelliMAX® Software featuring IntelliCAM® programming software and real world cutting data.

With innovative accessories such as the DualBRIDGE system, Tilt-A-Jet®, A-Jet®, and Rotary Axis, the 120X Series is a robust and versatile system that provides superior performance to maximize productivity and profitability.

Spark & Co. has been a distributor of OMAX waterjet cutting systems (PROTOMAX®, GLOBALMAX®, MAXIEM® and OMAX® series) for over a decade. No one is better equipped to meet your needs in waterjet, Laser (2D laser, Tube Laser, Shaping and Finishing.

For more information : https://www.omax.com/omax-waterjet/120x-series

MAXIEM 1530

MAXIEM 1530 OMAX 2652

OMAX 2652 OMAX 55100

OMAX 55100 Maxiem 1515

Maxiem 1515 Protomax

Protomax