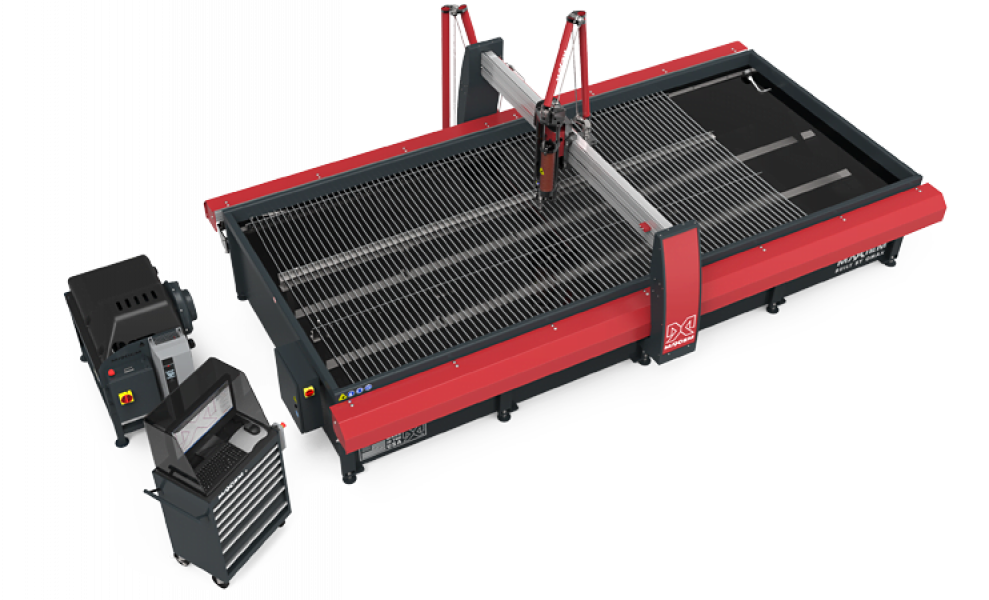

Bigger is better when it comes the The Maxiem 2040 Waterjet cutting machine, a robust jetmachining center designed for high capacity production.

The The Maxiem 2040 Waterjet cutting machine system can easily machine almost any material, from steel and titanium to carbon fiber, composites, glass, and more. With an X-Y cutting envelope of 13’ 10” x 6’ 7” (4,216 mm x 2,007 mm) a maximum cutting speed of 500 inches per minute (12,700 mm/min) and linear positioning accuracy of ±0.003” (±0.08 mm), this heavy-duty waterjet cutter can handle any job you throw at it.

Thanks to its highly efficient direct drive pump, programmable motorized Z-axis and a diamond-integrated MAXJET® 5i Nozzle, this robust waterjet machine delivers the highest nozzle horsepower in the industry with operating efficiency of up to 85% for faster, more efficient cutting.

The Maxiem 2040 Waterjet cutting machin uses substantially less cooling water than inefficient hydraulic intensifier pumps and boasts the lowest electrical consumption in the industry.

OMAX’s patent-pending IntelliTRAX® traction drive, the first motion control system designed specifically for abrasive waterjets, inside the X-Y Axis beams is fully enclosed inside coated steel covers for greater durability and reduced machine maintenance. The system incorporates a magnetic linear encoder and an electronic drive control for precise positioning.

Do more for less with this next generation waterjet machining center that can be set up for automated cutting to run unattended. Innovative IntelliMAX® Software Suite on the powerful controller allows for easy programming of complex parts, with a high-resolution screen providing a crystal-clear view of tool paths.

With the included Intelli-VISOR® System Monitoring aiding in scheduling maintenance downtime, your MAXIEM 2040 can remain at peak efficiency.

A host of additional accessories, such as the A-Jet® 5-axis cutting head, take the MAXIEM 2040 over the top in terms of productivity and profitability for your 3D machining needs.

Spark & Co. has been a distributor of OMAX waterjet cutting systems (PROTOMAX®, GLOBALMAX®, MAXIEM® and OMAX® series) for over a decade. No one is better equipped to meet your needs in waterjet, Laser (2D laser, Tube Laser, Shaping and Finishing.

For more information : https://www.omax.com/maxiem-waterjet/2040

MAXIEM 1530

MAXIEM 1530 OMAX 2652

OMAX 2652 OMAX 55100

OMAX 55100 Maxiem 1515

Maxiem 1515 Protomax

Protomax