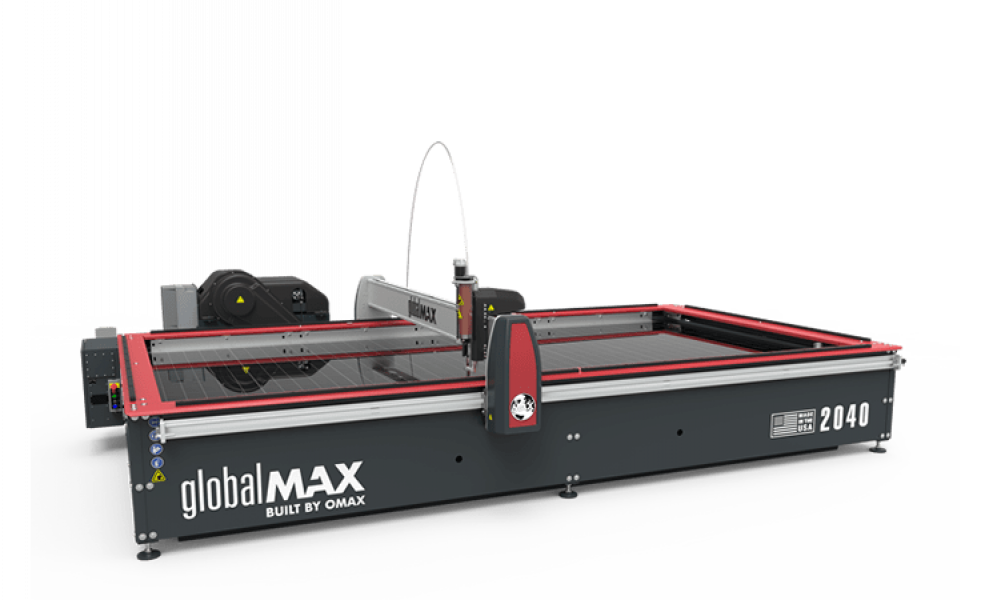

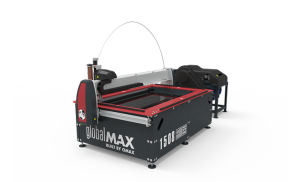

If you think a waterjet cutting machine with top-of-the-line features means sacrificing value or performance, the Globalmax 2040 waterjet built by OMAX will make you think twice!

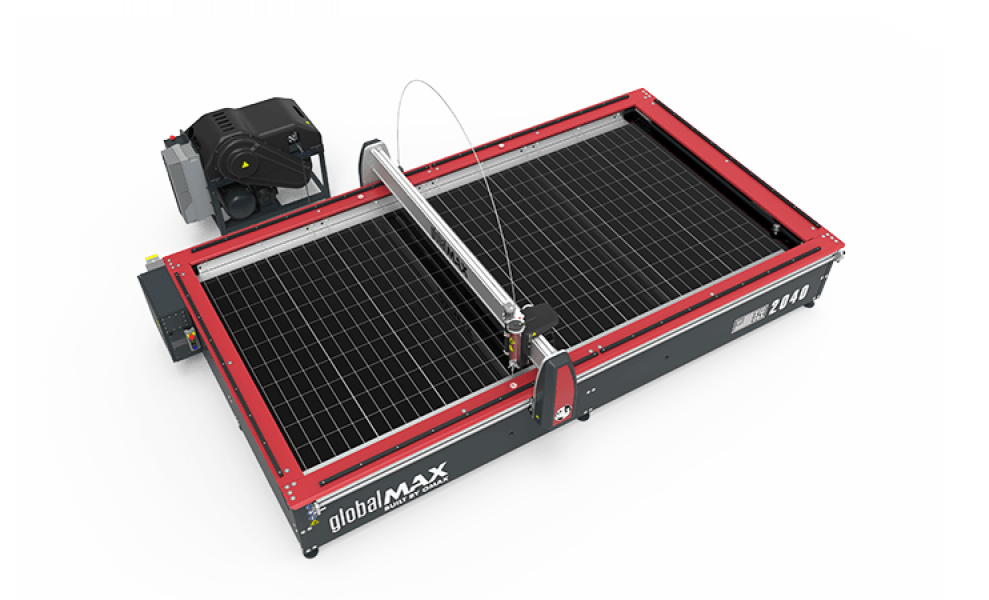

Featuring a 13’ 3” x 6’ 8” (4,038 mm x 2,032 mm) cutting bed that can support a maximum material load of 100 lb/ft2 (488 kg/m2) and a number of compatible accessories, this waterjet is ideal for shops that need to cut large parts or multiple nested parts from large sheets of material.

With a cutting speed of 500 in/minute (12 700 mm/min ) and linear positioning accuracy of ±0.003” (±0.08 mm), you can quickly and accurately cut a wide variety of materials and thicknesses, without any heat-affected zone, from aluminum, titanium, stone, carbon fiber to G10 composite and beyond.

Typical of Omax jetmachines, the Globalmax 2040 waterjet cutting machine comes equipped with state-of-the-art components and technologies. For example, an ultra-high efficiency direct drive pump runs quiet and clean, all the while converting over 85% of electrical power to pure cutting power.

If you look at what’s really important - the nozzle, and matching nozzle hydraulic horsepower and abrasive flow rate - the OMAX direct drive pump uses less electricity and less water, while also reducing component fatigue.

The lubricant-free, zero maintenance Omega Drive System attracts and retains garnet, offering a smoother transition from rotary motion to linear motion as compared to traditional rack and pinion drive systems.

What’s more, it features closed loop, brushless servo motors and anodized drive system components for longer life. Backlash is minimized and reliability proven once again thanks to the Omega Drive tooth engagement.

To this, add a superior X/Y positioning system for high precision machining, even in high-vibration manufacturing environments.

Import, draw and cut parts at the touch of a button thanks to OMAX IntelliMAX® Global operating software developed specifically for abrasive waterjet machines. Simple, fast and precise, the OMAX IntelliMAX Software Suite delivers extraordinary power and performance while remaining intuitive and user friendly.

Incorporating an advanced cutting model which automatically creates the optimal cutting path, this superior software automatically adjusts the speeds and accelerations around curves and corners to optimize the tool path for speed, precision, and square corners.

Fast and easy to program and even easier to use, IntelliMAX Global allows the parts to be machined as quickly as possible while still maintaining the highest tolerances and precise predictability in cutting speeds, taper and jet lag.

Powerful, efficient, affordable: the Globalmax 2040 waterjet cutting machine is a dynamic abrasive waterjet machining center with something for everyone, no matter the industry.

Spark & Co. has been a distributor of OMAX waterjet cutting systems (PROTOMAX®, GLOBALMAX®, MAXIEM® and OMAX® series) for over a decade. No one is better equipped to meet your needs in waterjet, Laser (2D laser, Tube Laser, Shaping and Finishing.

For more information : https://www.omax.com/globalmax-waterjet/2040

MAXIEM 1530

MAXIEM 1530 OMAX 2652

OMAX 2652 OMAX 55100

OMAX 55100 Maxiem 1515

Maxiem 1515 Protomax

Protomax