Waterjet cutting is a powerful and versatile industrial manufacturing process that utilizes a high-pressure machine and abrasive material to cut a variety of materials such as metal, stone, aluminum, and plastic. High-pressure water is combined with an abrasive material, such as garnet, to create a powerful jet that can easily cut through even the toughest materials. In Canada and around the world, waterjet cutting is valued for its numerous advantages, including precision, accuracy, and cost-effectiveness.

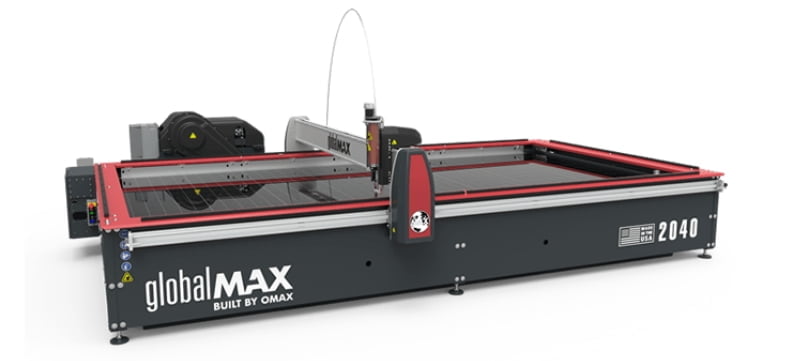

This cutting process is used on a wide range of materials using a cutting table and high-pressure water. During the cutting process, water is forced through a small nozzle at extremely high pressure (ranging from 20,000 PSI to 90,000 PSI), creating a fine, concentrated jet of water capable of accurately cutting thick materials. This is where renowned manufacturers such as OMAX, Flow, and KMT come in, producing high-quality equipment for this process.

To enhance cutting efficiency and reduce wear on parts, abrasive particles (such as garnet) are often added to the water stream. This abrasive water jet acts as a sandblasting process, using the abrasive particles to cut through the material.

Due to its versatility, waterjet cutting is a popular choice among manufacturers as it can be used to cut a variety of materials, including metals, plastics, composites, and even stone or glass. Additionally, because waterjet cutting does not produce a heat-affected zone (due to the low temperature of the water), it can be used to cut heat-sensitive materials or otherwise difficult-to-cut materials with other methods. It is a precise and cost-effective cutting method, ideal for a variety of industrial applications.

Waterjet cutting is a process used to cut a wide range of materials using high-pressure water and an abrasive substance. During the cutting process, water is pushed through a small nozzle at extremely high pressure (from 20,000 PSI up to 90,000 PSI), creating a fine, focused stream of water that is capable of cutting through thick materials with precision.

To increase cutting efficiency and reduce wear on the nozzle, abrasive particles (such as garnet) are often added to the water stream. This abrasive waterjet acts like a sandblaster, using the abrasive particles to cut through the material.

Waterjet cutting is considered a versatile and precise cutting method because it can be used to cut a variety of materials, including metals, plastics, composites, and even stone or glass. Additionally, because waterjet cutting produces no heat-affected zone (due to the low temperature of the water), it can be used to cut materials that are heat-sensitive or otherwise difficult to cut with other methods.

MAXIEM 1530

MAXIEM 1530 OMAX 2652

OMAX 2652 OMAX 55100

OMAX 55100 Maxiem 1515Laser Welding&CleaningA complete series of laser welding systems for various applications and materials.

Maxiem 1515Laser Welding&CleaningA complete series of laser welding systems for various applications and materials.