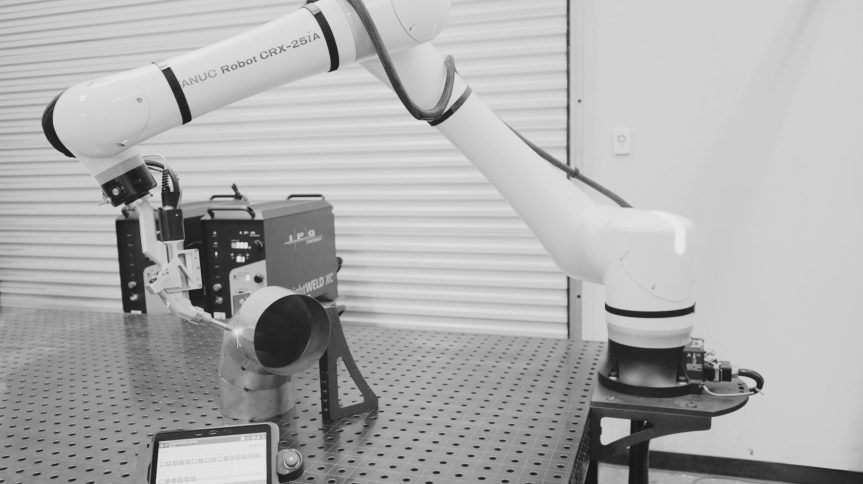

By integrating the expertise of leading industrial robotics partners, including FANUC, a global leader in industrial robots, Spark & Co delivers automated laser welding solutions that combine cutting-edge automation with proven reliability. This strategic collaboration enables the deployment of robotic laser welding cells recognized for their robustness, precision, and industrial performance, ensuring access to advanced technologies for clients seeking to modernize their manufacturing processes and increase operational efficiency.

By integrating the expertise of leading industrial robotics partners, including FANUC, a global leader in industrial robots, Spark & Co delivers automated laser welding solutions that combine cutting-edge automation with proven reliability. This strategic collaboration enables the deployment of robotic laser welding cells recognized for their robustness, precision, and industrial performance, ensuring access to advanced technologies for clients seeking to modernize their manufacturing processes and increase operational efficiency.

Adopting automated laser welding transforms the way businesses operate. Through robotic laser welding automation, it allows laser welds to be performed with unmatched speed, consistency, and high precision, significantly boosting productivity. These systems operate continuously, 24/7 if needed, reducing downtime and improving throughput across demanding production lines.

In terms of quality, the laser welding process guarantees accurate, repeatable welds with minimal human intervention. Real-time monitoring systems and optimized laser beam control help detect defects, maintain alignment, and ensure optimal fusion of joints, even in complex or high-precision assemblies.

This level of automation also empowers your workforce. By automating routine tasks, employees can shift their focus to higher-value responsibilities such as process validation, design, or advanced quality control. This enhances not only professional development but also innovation within the company.

Finally, safety is elevated thanks to built-in detection features, motion clamps, and secure enclosures, minimizing risks associated with manual welding. The result is a safer working environment and reduced costs tied to workplace incidents.

In short, automated welding with Spark & Co means faster output, better weld quality, improved worker safety, and greater adaptability to evolving industry demands in automotive battery assembly, metal fabrication, or high-precision component manufacturing.

MAXIEM 1530

MAXIEM 1530 OMAX 2652

OMAX 2652 OMAX 55100

OMAX 55100 Maxiem 1515

Maxiem 1515 Protomax

Protomax

By integrating the expertise of leading industrial robotics partners, including FANUC, a global leader in industrial robots, Spark & Co delivers automated laser welding solutions that combine cutting-edge automation with proven reliability. This strategic collaboration enables the deployment of robotic laser welding cells recognized for their robustness, precision, and industrial performance, ensuring access to advanced technologies for clients seeking to modernize their manufacturing processes and increase operational efficiency.

By integrating the expertise of leading industrial robotics partners, including FANUC, a global leader in industrial robots, Spark & Co delivers automated laser welding solutions that combine cutting-edge automation with proven reliability. This strategic collaboration enables the deployment of robotic laser welding cells recognized for their robustness, precision, and industrial performance, ensuring access to advanced technologies for clients seeking to modernize their manufacturing processes and increase operational efficiency.