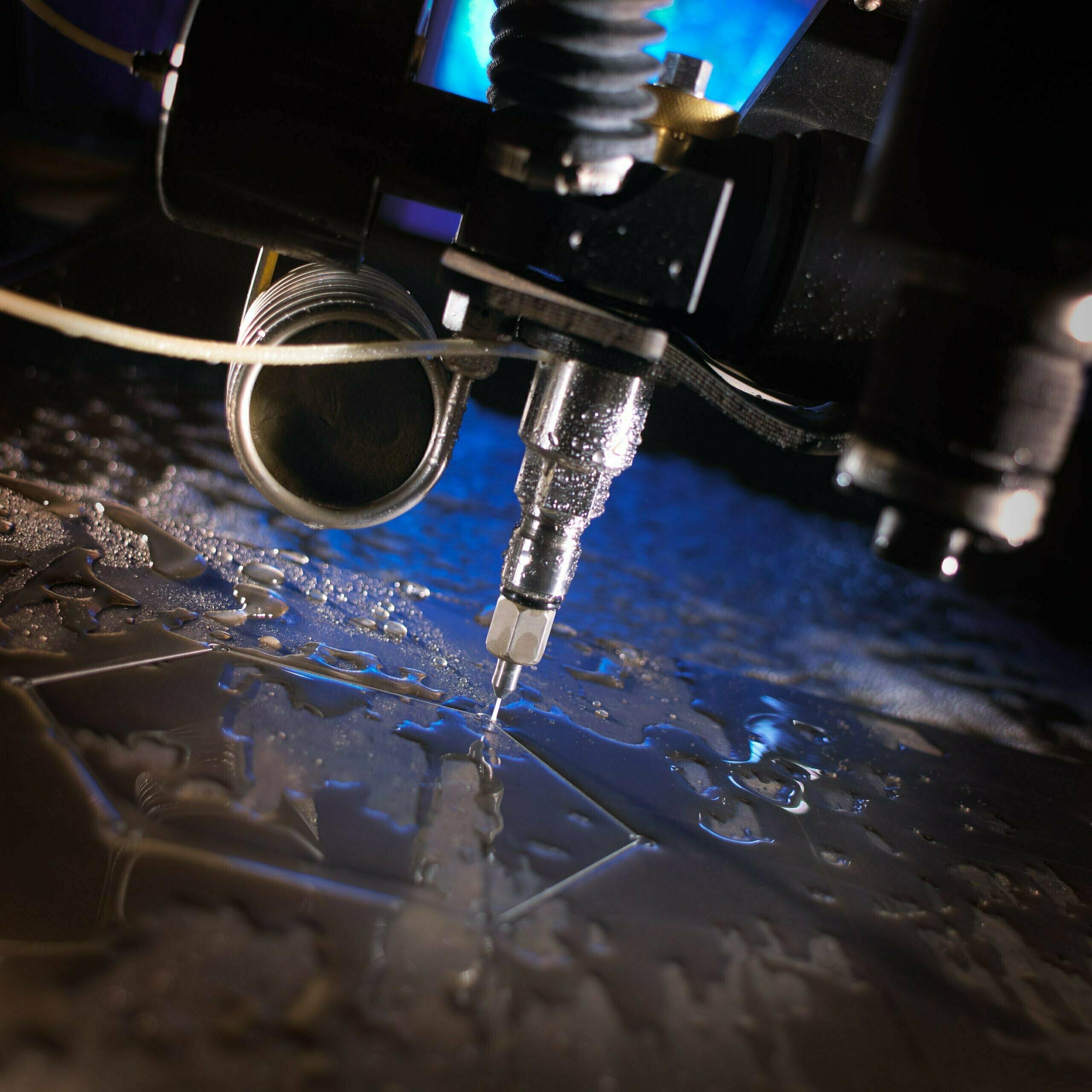

Buying a waterjet cutting machine? Investing in new equipment for your facility can be a daunting task, especially when it comes to purchasing something as important as a waterjet. Waterjets are widely used throughout the manufacturing and fabrication industries for their ability to cut through a variety of materials with precision and speed. However, before jumping into a purchase decision, there are some essential things you need to know. In this post, we’ll take a closer look at what plant managers should consider before buying a water jet cutting machine.

1-Material Type and Thickness :

Before purchasing a water jet cutting machine, you need to determine what type of materials you will be cutting and what thickness they will be. Different waterjets have varying capabilities when it comes to cutting different materials. Some may be able to cut through harder materials such as steel, while others may struggle. Additionally, some water jet cutting machines may have trouble cutting through thicker materials. Be sure to do your research before making a purchase to ensure you choose the best waterjet for your specific needs.

Thickness:

Water jet cutting machines are capable of cutting through both thin and thick materials. However, the thickness of the material will determine the power requirements for your waterjet. For example, if you’re cutting thicker materials, you’ll need a water jet cutter with a higher horsepower.

Type of Material:

Water jets cutter are versatile machines, and can cut through a variety of materials, including metal, plastic, rubber, glass, ceramics, and more. However, different waterjet machines will have different capabilities when it comes to cutting specific materials. For example, some machines will be better suited to cutting metals, while others are designed for softer materials like foam or rubber.

In addition to material type and thickness, it’s also important to consider the quality of the material. Using high-quality materials will produce better results when cutting and can help extend the life of your water jet cutting machine.

Water jets are highly versatile and can cut through almost any material. However, different types of materials require different types of waterjets. You should consider what types of materials you will be cutting, such as metal, stone, or composite materials, and choose a water jet cutting machine that is best suited for those materials.

Operating Costs :

It’s important to consider the costs associated with operating a water jet cutter. Waterjets require a some amount of water and electricity to function properly. Additionally, the cost of replacement parts and maintenance needs to be taken into consideration. Understanding the total cost of ownership for your water jet will help you make a more informed purchasing decision.

Power consumption:

Water jets cutter can more expensive to run then laser, but gives you more flexibility on materials you can cut. especially if you’re operating them at high pressures. Depending on your electricity rates, the cost of power consumption can add up quickly.

Abrasive materials:

Most water jet machines use abrasive materials such as garnet to help cut through hard materials. Make sure these materials can be available near you ..

Maintenance and repair:

Like any industrial machinery, water jets cutting require regular maintenance and repairs to keep them running smoothly like any machine tool. This can include things like replacing worn or damaged parts, cleaning and replacing filters, and performing routine maintenance tasks.

Labor:

Operating a water jet cutting machines requires skilled labor, but easy to train on existing softwares , which can be expensive. Depending on your location, labor rates can vary widely, so it’s important to factor this into your cost analysis.

Disposal of waste materials:

Abrasive water jets cutters produce a lot of waste materials, including abrasive particles and materials that have been cut. Disposing of these materials can be expensive, especially if you’re dealing with hazardous materials.

2- Cutting Speed :

Water jet cutting speed is affected by a number of factors, including the type and thickness of the material being cut, the abrasive used, the machine’s horsepower, and the desired accuracy of the cut.

Some materials, such as soft materials like foam, can be cut relatively quickly and efficiently with waterjets, while harder materials like steel and titanium will take longer. As a general rule of thumb, the thicker the material, the slower the cutting speed will be.

Different abrasive materials used with the waterjet can also affect the cutting speed. For example, garnet is the most commonly used abrasive for waterjets and provides a good balance between cutting speed and accuracy. However, other abrasive materials may cut faster, but at the cost of precision and accuracy.

The horsepower of the waterjet machine is another important factor in determining cutting speed. Higher horsepower machines will be able to cut through materials faster than lower horsepower machines.

Finally, the desired accuracy of the cut will also affect the cutting speed. Cutting a material with high accuracy and precision will take longer than cutting a material with looser tolerance requirements.

Overall, water jet cutting speed varies depending on several factors, but can typically range from a few inches per minute to several hundred inches per minute. When selecting a waterjet, it’s important to consider the speed requirements for your specific needs, and to choose a machine that meets those requirements while still providing the precision and accuracy you need.

3-Maintenance Requirements of the pump:

Like all equipment, waterjets require regular maintenance to keep them in top condition. However, the maintenance required for one water jet cutting machines may differ from another. Before making a purchasing decision, research the maintenance requirements of the water jet cutter you are considering. Knowing what you’re getting into ahead of time will help you better plan and budget for maintenance costs.

4- Operator Training

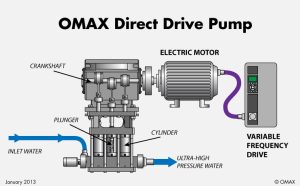

The operating cost of a direct-drive waterjet pump is typically lower than an intensifier pump. This is because direct-drive pumps require less maintenance and have lower operational costs due to their efficiency and reliability. Additionally, they create less noise, generate less heat and require fewer replacement parts compared to intensifier pumps.

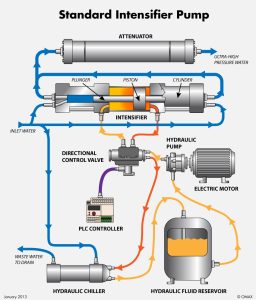

On the other hand, intensifier pumps are more powerful and can handle multiple cutting heads in water only applications, but come with higher operational costs. They require more maintenance, generate more noise and heat, and require frequent replacement parts compared to direct-drive pumps.

Ultimately, the decision between direct drive or intensifier depends on your budget and cutting needs. If you need greater power for tougher materials but are on a tight budget, you may want to consider looking into refurbished waterjets as they tend to be cheaper than new models.

Regardless of which type of pump you choose, it’s important to understand the difference in operation cost between direct-drive pumps and intensifiers before making a purchase decision on a high pressure pump. Finally, it’s important to consider the training required for operators to properly use a water jet cutting machine. A waterjet is a powerful piece of equipment and should be used by trained professionals. Depending on the complexity of your chosen water jet cutting, the amount of training required may vary. Be sure to factor in the cost and time required for operator training.

5- Having local support and service:

Are you a business owner in Canada looking to purchase waterjet cutting machines ? Choosing a waterjet cutting machine from our company not only provides you with cutting-edge technology but also local customer service and technical support.

Having local service and support means fast and efficient issue resolution, reduced downtime, and access to expert advice specific to the Canadian market. A team of experienced professionals is available to provide timely and reliable after-sales support, including maintenance and repair services.

When having local support, you can trust that your investment in a water jet cutting machine is backed by a team that understands the unique needs of Canadian businesses. We are here to ensure your continued success in the manufacturing industry.

Don’t settle for anything less than the best. Choose a water jet cutting machine from our company and experience the benefits of local service and support in Canada. Contact us today to learn more about how we can help take your business to the next level.

7-Pump Type Direct Drive or intensifier:

Are you trying to decide between a direct-drive pump and an intensifier pump high pressure pump for your waterjet cutting needs? It’s important to understand the differences between the two.

Direct Drive :

Direct-drive waterjet pumps use a crankshaft system and alternating pistons to generate high-pressure water. These pumps are known for their efficiency and reliability, as well as their lower maintenance costs. Additionally, direct-drive pumps are less noisy and produce less heat compared to intensifier pumps.

Intensifier :

On the other hand, intensifier waterjet pumps use hydraulic pressure to intensify a smaller amount of water, creating a high-pressure stream. These pumps are powerful and can handle mutiple heads better, but they require more maintenance and are typically louder and produce more heat compared to direct-drive pumps.

Ultimately, the choice between direct-drive and intensifier pumps depends on your specific cutting needs and budget. Do you prioritize efficiency and lower maintenance costs, or do you need the power to handle more cutting heads in water only applications? Understanding the differences between these two types of pumps can help you make an informed decision.

If you’d like to learn more about waterjet pump technology and how to choose the right pump for your needs, check out these helpful resources:

Local parts availability :

When considering buying waterjet cutting machines in Canada , one important factor to keep in mind is the availability of parts to keep your machine running smoothly. Having easy access to replacement parts is crucial to ensuring that your waterjet cutting machine operates at peak efficiency while minimizing downtime and maintaining productivity.

A water jet cutter that is down due to the unavailability of parts can cause delays in production, missed deadlines and potential financial losses. In addition, using substandard parts or waiting for replacement parts to arrive can lead to poor quality cutting, inaccuracies and lower quality work overall.

Therefore, when purchasing a waterjet cutting machine, it is important to inquire about the availability of parts from the manufacturer, as well as any authorized service and repair centers in your area.

Buying an abrasive waterjet cutting machine from a reputable manufacturer or distributor with a wide range of parts inventory ensures timely and effective repairs or maintenance, improving machine longevity and allowing for uninterrupted operations. Manufacturers who maintain a large inventory of parts and have partnered with local repair centers to ensure that they are available when needed significantly improve the reliability of their systems.

When the availability of parts is ensured, you can maximize the potential of your waterjet cutting machine while reducing the overall headache associated with parts failure. Choose wisely when making your purchase to enjoy long-term performance and productivity for your manufacturing or cutting business.

9-Abrasive cutting or water only application or with garnet?

Abrasive waterjet cutting is the process of using a combination of water, abrasive particles and high pressure to cut through materials like metal, stone and glass. This method is typically used for thick materials that are too hard or too brittle for traditional cutting tools.

Abrasive waterjet cutting is more precise than traditional methods as it offers greater control over the process, resulting in a cleaner, smoother cut with minimal thermal distortion. Abrasive particles are suspended in the jet stream to help break up the material being cut, allowing for faster and more efficient cuts.

On the other hand, water-only cutting uses only pressurized water to make cuts through softer materials such as paper, foam or soft plastics. It requires less equipment than abrasive cutting so it is often seen as an attractive option for low-budget projects. However, this method lacks precision compared to abrasive cutting and is limited by the type of materials it can be used on.

10-Importance of Software:

When it comes to buying a waterjet system, it’s not just about the hardware. The software used to operate the machine is just as important. In fact, having the right software can mean the difference between a smooth, efficient cutting process and a frustrating, error-prone one.

One key feature to look for in waterjet cutting software is compatibility with your specific waterjet model. This will ensure that the software is optimized for your machine and can take full advantage of its capabilities

Another important consideration is ease of use. Look for a software that offers a user-friendly interface and streamlined workflow. This will save time and reduce the likelihood of errors.

Finally, consider the software’s capabilities in terms of design and programming. Look for features such as CAD/CAM integration and the ability to import 3D models. This will allow you to create complex, detailed designs with ease and precision.

In short, don’t overlook the importance of software when buying a waterjet. With the right software, you can unlock the full potential of your water jet cutter machine and streamline your cutting process for maximum efficiency and accuracy.

Warranty and Support: Waterjets systems are complex machines that require ongoing support and maintenance. Before buying a waterjet, make sure the manufacturer offers a comprehensive warranty and support program to ensure your machine operates at peak efficiency.

Conclusion:

Purchasing a water jet cutter is a significant investment for any facility. It’s crucial to take the time to consider all the necessary factors before making a purchase decision. Knowing what type of materials you’ll be cutting, the operating costs involved, cutting speed, maintenance requirements, and operator training can help you make an informed decision that will benefit your facility in the long run. Taking a little extra time to do your research will pay off in the end.

Sources:

- https://www.omax.com/en/us/learn/what-to-consider-before-buying

- https://www.youtube.com/watch?v=_iiD1kwjh8Q

- https://www.omax.com/en/us/intellimax-software

- https://www.hypertherm.com/en-US/landing-pages/cam/pronest-lt-omax?region=NART

- https://www.canadianmetalworking.com/canadianfabricatingandwelding/article/fabricating/understanding-waterjet-pump-technology

- https://www.omax.com/en/us/learn/how-does-waterjet-work

- https://waterjets.org/archive/buyers-guide/general/choosing-a-pump/

- https://www.omax.com/en/us/learn/how-does-waterjet-work