If you’re looking for a new machine to broaden your shop's versatility and increase your production capacity, then scale up for big production runs with the largest waterjet cutting table MAXIEM® 3060 abrasive waterjet and watch how efficiency turns into productivity!

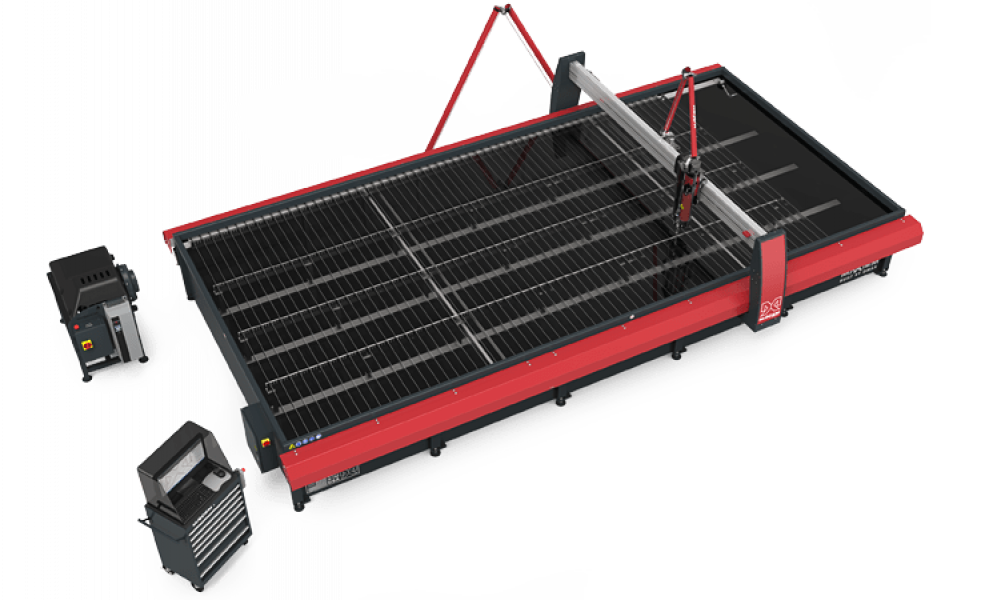

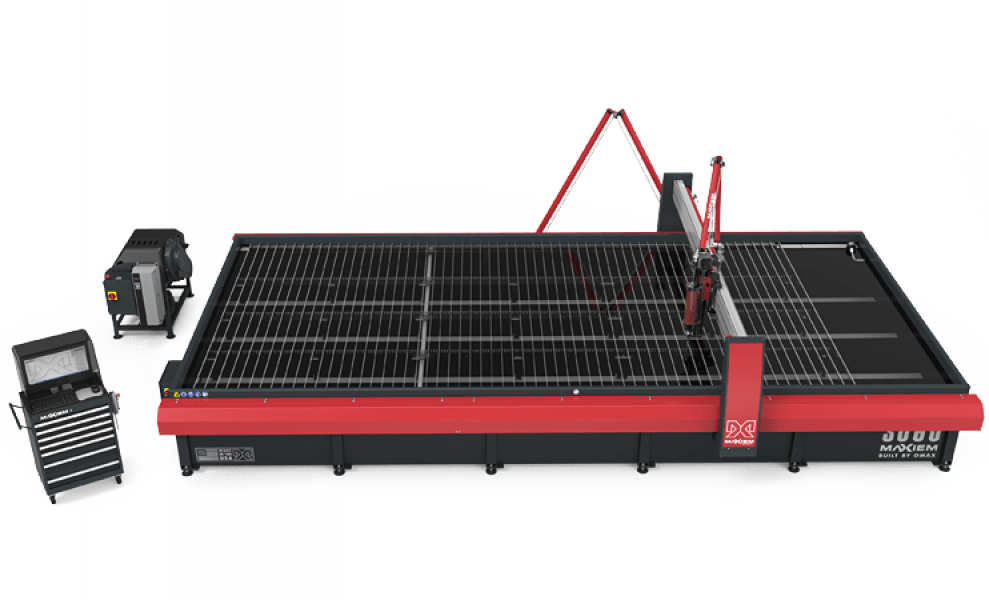

The MAXIEM 3060 has a 20’ 6” x 10’ 2” (6,248 mm x 3,099 mm) cutting table giving it the largest cutting table of the 8 MAXIEM abrasive waterjet machines. To this, add a maximum cutting speed of 500 inches per minute (12,700mm/min) and a linear positioning accuracy of +0.0030” (+0.08 mm) for the ultimate in speed and accuracy.

OMAX isn’t the top name in waterjets for nothing: like all MAXIEM abrasive waterjets, the largest waterjet cutting table 3060 delivers the highest nozzle horsepower in the industry with operating efficiency of up to 85% thanks to extremely efficient, ultra high-pressure drive pump technology and a diamond-integrated MAXJET® 5i nozzle for faster, more efficient cutting.

IntelliTRAX® linear drive technology translates into superior performance within harsh abrasive waterjet environments. Magnetic encoders provide one-micron resolution location feedback for exact positioning of the cutting head at all times. Designed specifically for abrasive waterjets, the system lasts longer and requires less maintenance because it is fully enclosed inside coated steel covers inside the X-Y axis beams.

Great hardware deserves great software, and the IntelliMAX® software suite delivers in every way. Program complex parts and set up for automated, unattended cutting at the touch of a button with user-friendly intuitive software on a powerful controller featuring a high-resolution widescreen display providing a crystal-clear view of tool paths. The mobile control station provides flexibility in controller positioning to suit your space.

Optional accessories, such as the A-Jet® for 5-axis cutting and taper compensation, can add multi-axis versatility, cut pipes, automate taper elimination, clean your tank, and much more.

Planned maintenance makes the difference between uptime and downtime. Optional IntelliVISOR® EX system monitoring expands your jetmachining capabilities and dramatically improves production.

Spark & Co. has been a distributor of OMAX waterjet cutting systems (PROTOMAX®, GLOBALMAX®, MAXIEM® and OMAX® series) for over a decade. No one is better equipped to meet your needs in waterjet, Laser (2D laser, Tube Laser, Shaping and Finishing.

For more information : https://www.omax.com/maxiem-waterjet/3060

MAXIEM 1530

MAXIEM 1530 OMAX 2652

OMAX 2652 OMAX 55100

OMAX 55100 Maxiem 1515Laser Welding&CleaningA complete series of laser welding systems for various applications and materials.

Maxiem 1515Laser Welding&CleaningA complete series of laser welding systems for various applications and materials.