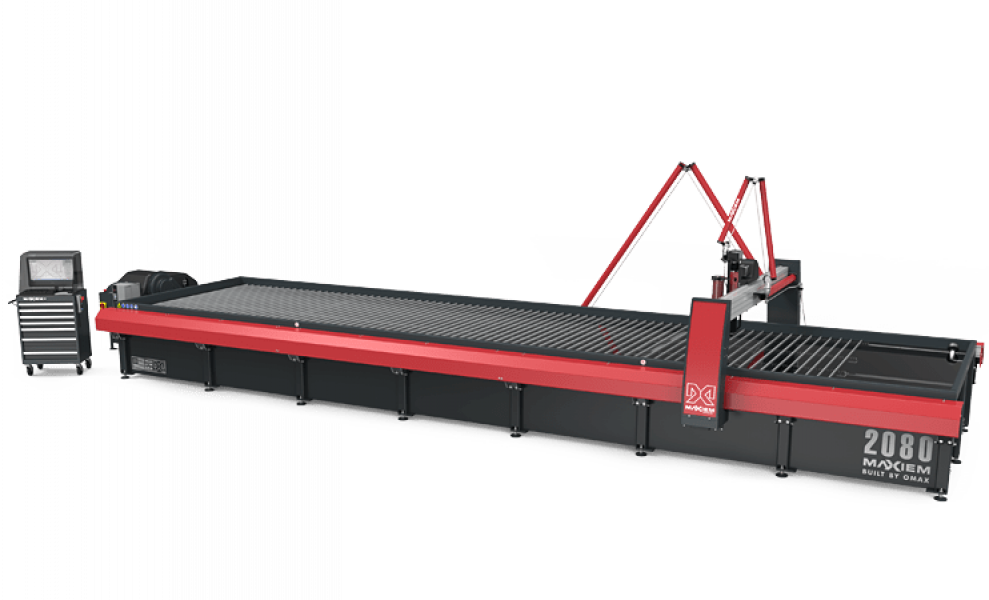

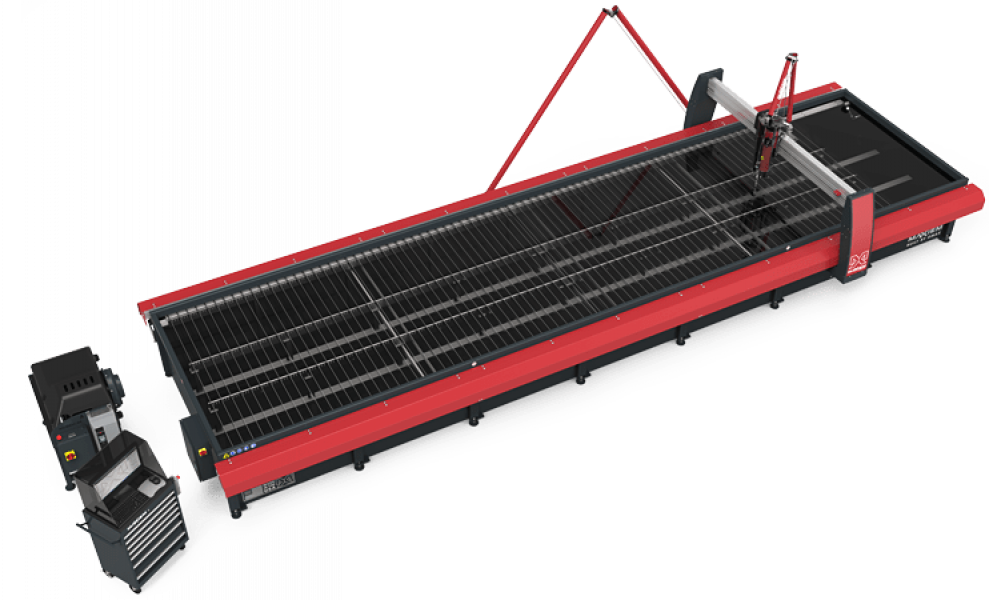

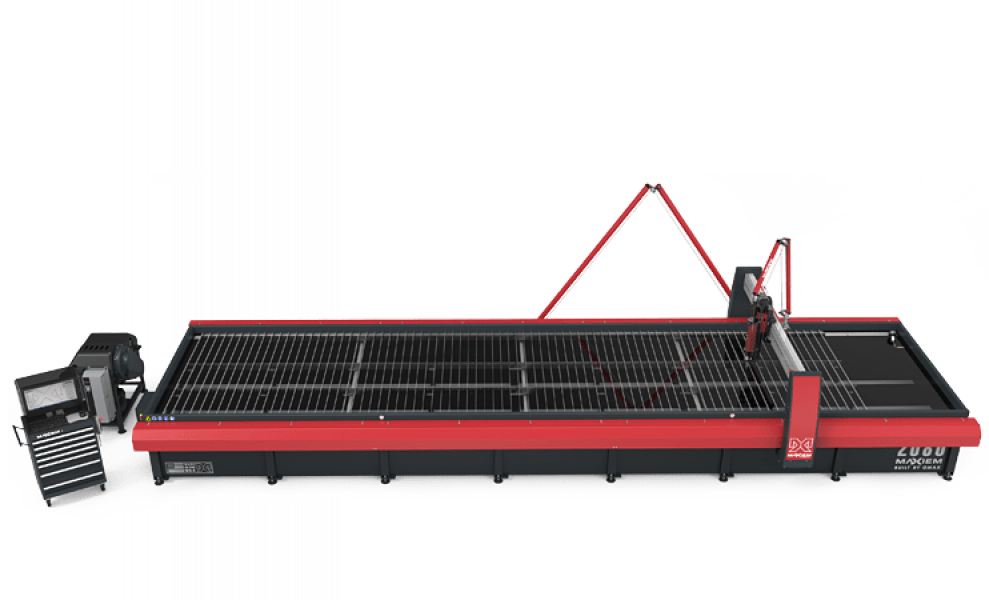

Premium performance and high output come together in this robust, affordable waterjet cutter: the Large scale waterjet cutting machine MAXIEM® 2080, built to optimize your full-scale machining operations.

The large scale waterjet cutting machine MAXIEM 2080 abrasive waterjet system boasts an X-Y cutting envelope of 27’ 2” x 6’ 7” (8,280 mm x 2,007 mm) a maximum cutting speed of a maximum cutting speed of 500 inches per minute (12,700 mm/min) and linear positioning accuracy of ±0.003” (±0.08 mm).

A real workhorse, this high-performance waterjet machine can handle virtually any material, from steel and titanium to carbon fiber, composites, glass, and more. A clean, cold cutting process, it doesn’t leave any heat affected zones or affect material integrity for reduced secondary operations.

Designed with similar bells and whistles as higher end models, the large scale waterjet cutting machine MAXIEM 2080 abrasive waterjet cutting machine delivers the highest nozzle horsepower in the industry with operating efficiency of up to 85% thanks to extremely efficient, ultra high-pressure drive pump technology and a diamond-integrated MAXJET® 5i nozzle for faster, more efficient cutting.

IntelliTRAX® linear drive technology translates into superior performance within harsh abrasive waterjet environments. Magnetic encoders provide one-micron resolution location feedback for exact positioning of the cutting head at all times. Designed specifically for abrasive waterjets, the system lasts longer and requires less maintenance because it is fully enclosed inside coated steel covers inside the X-Y axis beams.

The mobile control station lets you set up where it is most convenient, while IntelliMAX® software on the powerful controller with a high-resolution widescreen display allows you to quickly and easily program parts as complex as you please. You can even configure the waterjet machine for automated cutting, letting it run unattended to free up manpower for other tasks.

Optional accessories such as the A-Jet® for 5-axis cutting and taper compensation and IntelliVISOR® EX for expanded system monitoring expand your jetmachining capabilities and dramatically improve production.

Spark & Co. has been a distributor of OMAX waterjet cutting systems (PROTOMAX®, GLOBALMAX®, MAXIEM® and OMAX® series) for over a decade. No one is better equipped to meet your needs in waterjet, Laser (2D laser, Tube Laser, Shaping and Finishing.

For more information : https://www.omax.com/maxiem-waterjet/2080

MAXIEM 1530

MAXIEM 1530 OMAX 2652

OMAX 2652 OMAX 55100

OMAX 55100 Maxiem 1515Laser Welding&CleaningA complete series of laser welding systems for various applications and materials.

Maxiem 1515Laser Welding&CleaningA complete series of laser welding systems for various applications and materials.