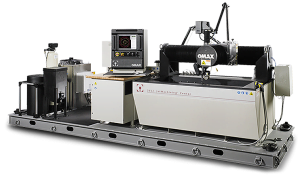

Take OMAX Mobile waterjet cutting machine ,wherever you need it with the OMAX® Mobile JetMachining Center, an advantageous cutting solution designed for machining in the field.

Essentially, the extremely durable and reliable system is a transportable abrasive waterjet shop mounted to a steel base with forklift access points, so the entire system can be quickly and easily moved.

System components rest on a durable, epoxy-coated platform that features metal tie-down rings for safe and secure shipping, a proven OMAX table, pump, and PC-based controller technology.

As quick, efficient and precise as in-shop models, the OMAX Mobile JMC does the job – and then some – for oil field maintenance, high-rise building construction, shipbuilding, onshore/offshore oil exploration and maintenance; and other industries requiring a self-contained cutting shop in a dynamic work environment.

The Omax Mobile Waterjet cutting machine , delivers precisely accurate, multi-axis parts quickly and consistently in almost any material, maximizing machining throughput. Built tough, it can easily machine almost any material and thicknesses, from steel and titanium to carbon fiber, composites, glass, and more.

Cut fast and clean thanks to a programmable, motorized Z-Axis with a precision, diamond-integrated OMAX MAXJET®5i nozzle Assembly, leaving behind satin-smooth edges with little to no secondary operations.

With an X-Y cutting envelope of 4’ 4” x 2’ 2” (1,321 mm x 660 mm) a maximum cutting speed of 180 inches per minute (4,572 mm/min) and a linear positioning accuracy of +0.0010” (±0.0254 mm), this mobile waterjet cutter allows you to run at peak efficiency no matter where your work takes you.

Completely assembled and factory tested, the Mobile JetMachining Center includes an EnduroMAX® direct drive pump system offering the highest nozzle horsepower in the industry; chiller, water softener System, and a 100lb-bulk hopper for abrasive storage. Rapid, centralized setup for air, power, water, and drain allows operators to have an activated system in a matter of minutes.

Spark & Co. has been a distributor of OMAX waterjet cutting systems (PROTOMAX®, GLOBALMAX®, MAXIEM® and OMAX® series) for over a decade. No one is better equipped to meet your needs in waterjet, Laser (2D laser, Tube Laser, Shaping and Finishing.

More Information : https://www.omax.com/omax-waterjet/mobile-jmc

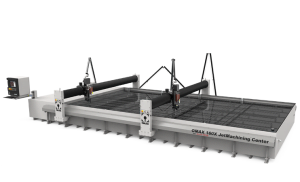

MAXIEM 1530

MAXIEM 1530 OMAX 2652

OMAX 2652 OMAX 55100

OMAX 55100 Maxiem 1515

Maxiem 1515 ProtomaxLaser Welding&CleaningA complete series of laser welding systems for various applications and materials.

ProtomaxLaser Welding&CleaningA complete series of laser welding systems for various applications and materials.