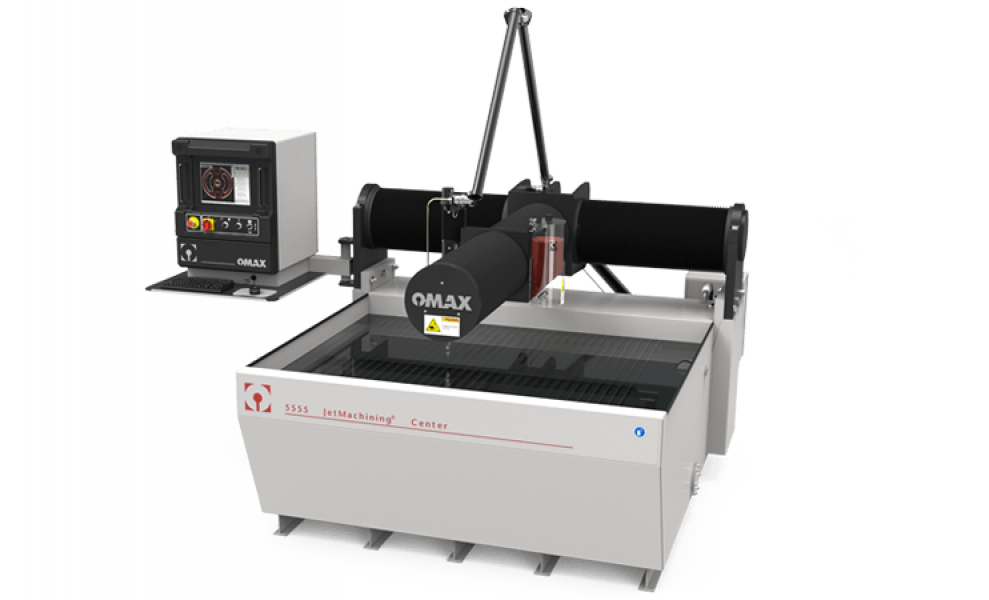

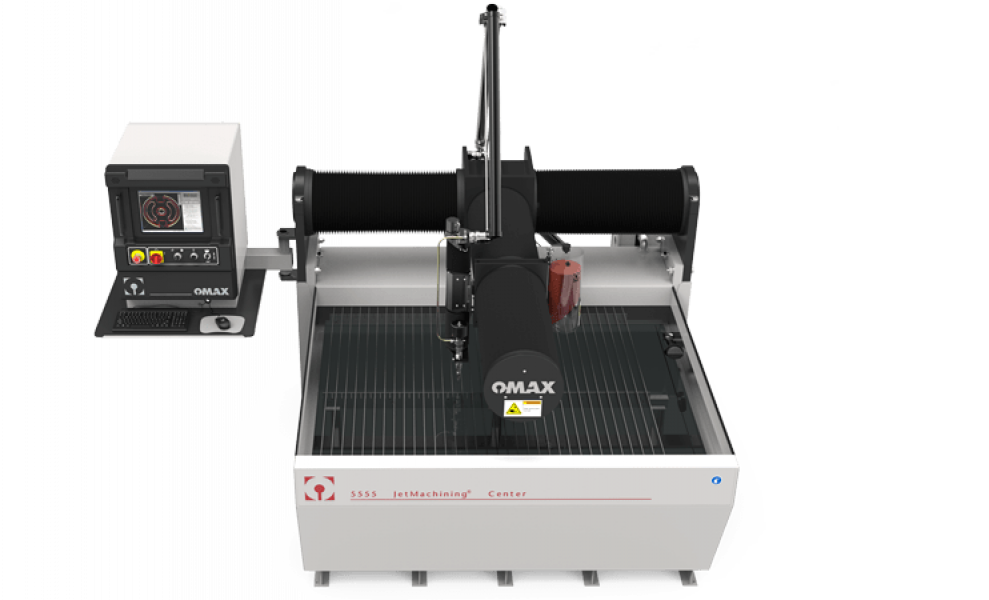

The fast, efficient, and precise Omax 5555 waterjet cutting machine provides top performance in waterjet machining of complex parts. Tried and true, this mid-sized cantilever style waterjet machines a wide range of materials and thicknesses, from metals and composites to glass and plastics.

Cold cutting is a great advantage of waterjet technology as the process does not create heat-affected zones or mechanical stresses, leaving the integrity of the material intact. Edges are satin-smooth and require less secondary finishing operations.

Its 4’ 7” x 4’ 7” (1,397 mm x 1,397 mm) X-Y cutting area is ideal for rapid prototyping and just-in-time manufacturing of small to medium-sized parts. With simple fixturing and easy access to the cutting table, setup times are significantly reduced, increasing productivity and profitability.

The Omax 5555 waterjet cutting machine boats a cutting tolerance of ±0.001″ (±0.025 mm), a maximum speed of 180 inches/min (4,572 mm/min) and a completely sealed and protected ball-screw drive system, making it the ideal choice for shops cutting projects with smaller dimensions but needing high precision.

OMAX waterjets feature an eco-friendly “green” system that uses only natural garnet abrasive and water in the cutting process. Another plus: no noxious fumes, liquid or oils are used in, or caused by, the machining process.

Fast and precise IntelliCAM® software offers two tools in one, quickly and easily generating 2D or 3D tools paths from 3D models. With the included Intelli-VISOR® System Monitoring, you can schedule maintenance downtime to keep running at peak efficiency.

EnduroMAX® direct drive pump technology delivers the highest nozzle horsepower in the industry for faster cutting with operating efficiencies of up to 85% and this, with over 1,000 hours between maintenance for increased uptime.

Standard features include a high-quality, integrated OMAX MAXJET® 5i Nozzle for more accurate and consistent jet alignment, which ultimately prolongs mixing tube life and delivers better quality cuts over the nozzle assembly life. Work clean, safe and quiet with the Rapid Water Level Control for submerged cutting below 80 dBA.

Optional accessories such as the bulk abrasive delivery system, scissor-style hard plumbing for added safety and reliability, tilt-a-jet taper eliminating abrasive jet cutting head and variable speed solids removal system (VS-SRS) expand your jetmachining capabilities and dramatically improve production.

Spark & Co. has been a distributor of OMAX waterjet cutting systems (PROTOMAX®, GLOBALMAX®, MAXIEM® and OMAX® series) for over a decade. No one is better equipped to meet your needs in waterjet, Laser (2D laser, Tube Laser, Shaping and Finishing.

For more information : https://www.omax.com/omax-waterjet/5555

MAXIEM 1530

MAXIEM 1530 OMAX 2652

OMAX 2652 OMAX 55100

OMAX 55100 Maxiem 1515

Maxiem 1515 ProtomaxLaser Welding&CleaningA complete series of laser welding systems for various applications and materials.

ProtomaxLaser Welding&CleaningA complete series of laser welding systems for various applications and materials.