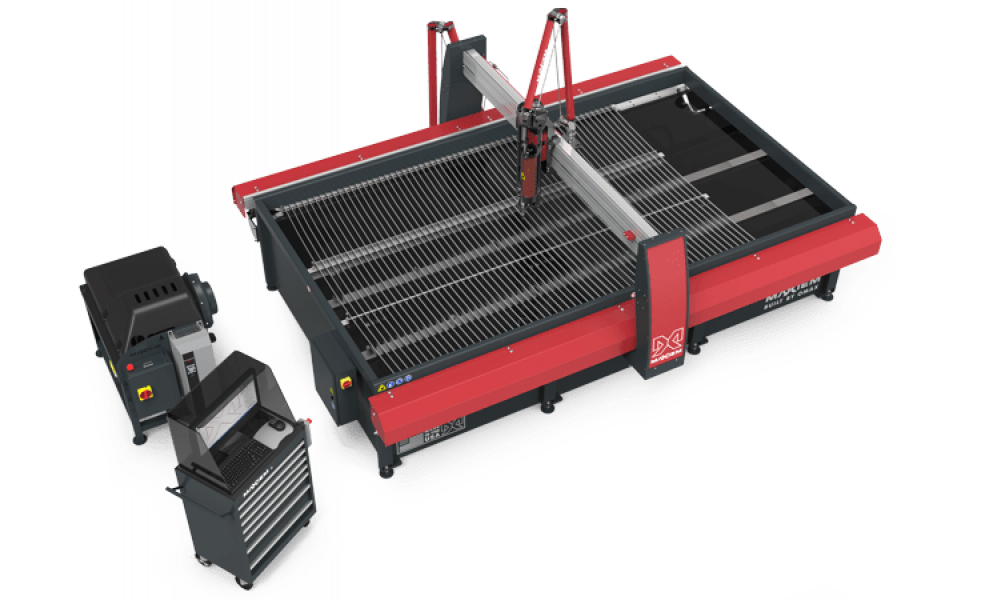

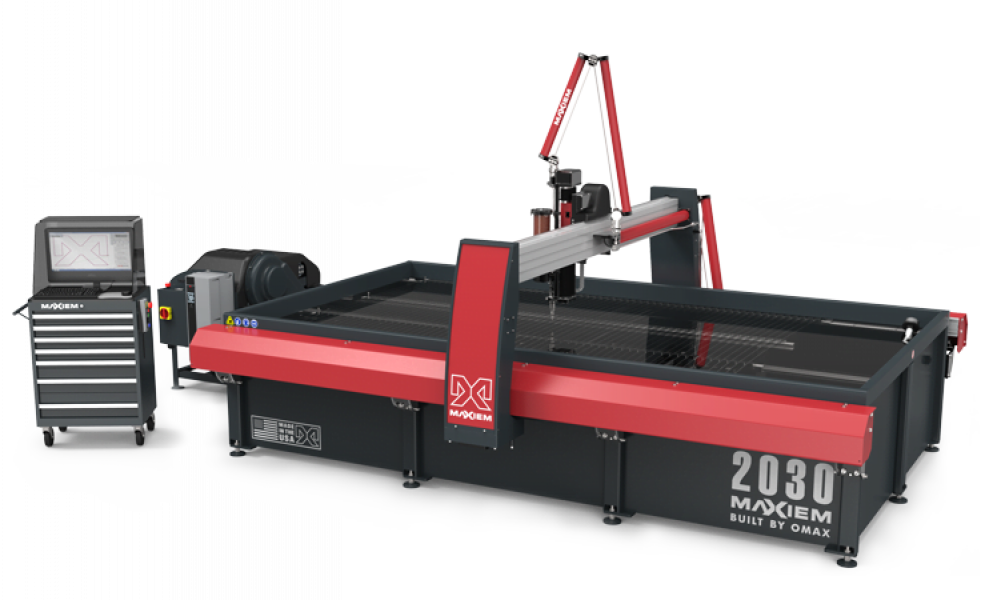

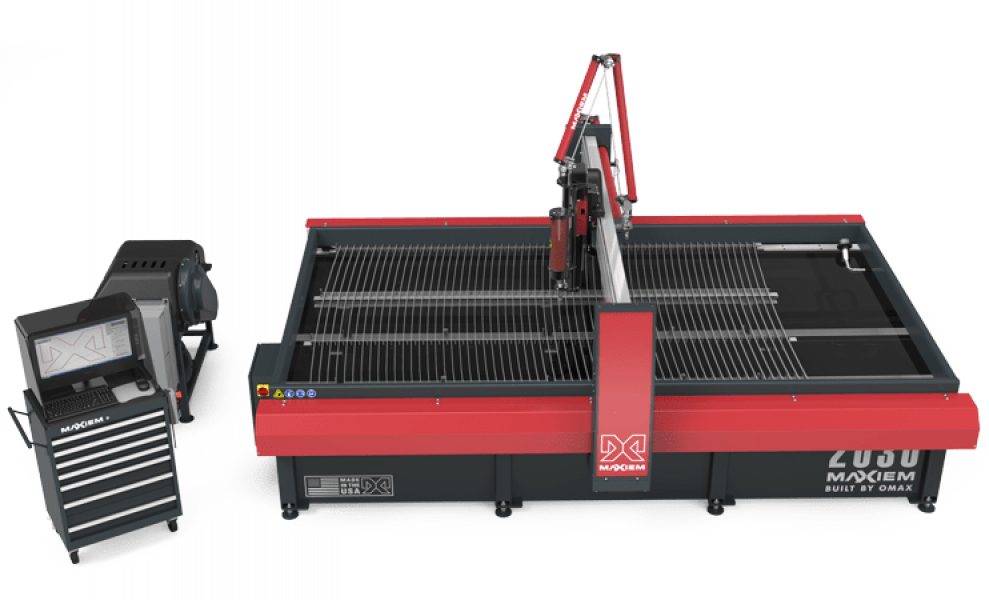

The Maxiem 2030 waterjet machining center by OMAX is good to go for large-scale precision machining for oversized, nested multiple parts or otherwise, making it a prime choice of equipment for mainstream job shops and OEMs.

With a cutting speed of 500 inches per minute (12,700 mm/min) and linear positioning accuracy of ±0.003” (±0.08 mm), you can quickly and accurately cut a wide variety of materials and thicknesses, without any heat-affected zone, from aluminum, titanium, glass, plastic, carbon fiber and beyond. No matter the material, this aquajet cutter leaves behind a satin-smooth edge, reducing secondary operations.

Typical of OMAX jetmachines, the Maxiem 2030 waterjet cutting machine comes equipped with state-of-the-art components and technologies. For example, an ultra-high efficiency direct drive pump delivers the highest nozzle horsepower on the market, all the while converting over 85% of electrical power to pure cutting power.

No noxious gases, liquid or oils are used in, or caused by, the machining process, plus it features an environmentally-friendly “green” system is designed for clean and quiet operation, using substantially less cooling water than inefficient hydraulic intensifier pumps and boasting the lowest electrical consumption in the industry.

The innovative IntelliMAX® Software Suite on the powerful controller allows for easy programming of complex parts, with a high-resolution screen providing a crystal-clear view of tool paths.

Crafting complex parts is a breeze thanks to optional accessories such as the A-Jet® for 5-axis cutting and taper compensation, rapid water level control for submerged cutting, and collision sensing terrain follower for machining irregular surfaces expand your jetmachining capabilities and dramatically improve production.

The MAXIEM line of abrasive waterjet machining centers meet a wide range of needs and incorporate proven technologies capable of providing a cost effective, affordable and highly productive solution to users. Configured for your business with broad accessory compatibility, MAXIEM built by OMAX is manufactured entirely in the United States.

Spark & Co. has been a distributor of OMAX waterjet cutting systems (PROTOMAX®, GLOBALMAX®, MAXIEM® and OMAX® series) for over a decade. No one is better equipped to meet your needs in waterjet, Laser (2D laser, Tube Laser, Shaping and Finishing.

For more information : https://www.omax.com/maxiem-waterjet/2030

MAXIEM 1530

MAXIEM 1530 OMAX 2652

OMAX 2652 OMAX 55100

OMAX 55100 Maxiem 1515

Maxiem 1515 ProtomaxLaser Welding&CleaningA complete series of laser welding systems for various applications and materials.

ProtomaxLaser Welding&CleaningA complete series of laser welding systems for various applications and materials.