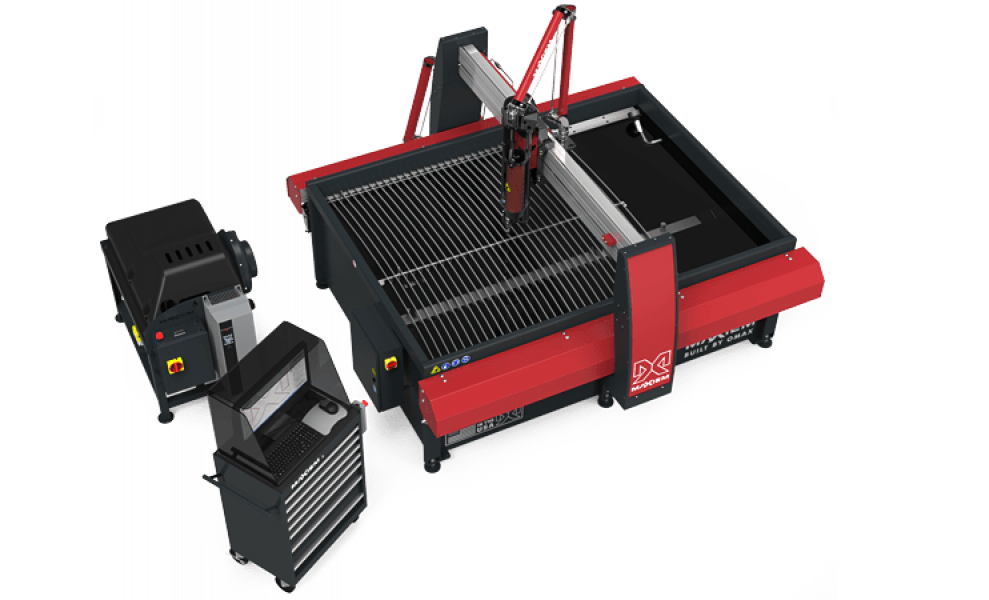

Faster, smoother and more accurate, the compact, high-performance the Waterjet Maxiem 1515 cutting machine is ideal for a wide range of machining needs.

With an ample cutting area that easily fits up to 5′ 2" x 5′ 2" (1,575 mm x 1,575 mm) material stock, the Waterjet Maxiem 1515 JetMachining Center is an excellent fit for fabrication and job shops.

The Waterjet Maxiem 1515 machines a wide range of materials and thicknesses, from metals and composites to glass and plastics. It leaves behind a satin-smooth edge, reducing secondary operations.

Its enhanced Intelli-TRAX® linear encoder system is optimized for the abrasive waterjet environment and is capable of adapting to irregular surfaces while maintaining high positioning accuracy. The digital linear encoder provides instant feedback to the control station, specifying the exact position of the head at all times.

Thanks to its highly efficient direct drive pump, this unbeatable waterjet machine delivers the highest nozzle horsepower in the industry with operating efficiency of up to 85% for faster, more efficient cutting.

MAXIEM uses substantially less cooling water than inefficient hydraulic intensifier pumps and boasts the lowest electrical consumption in the industry.

Simple, fast and precise, the OMAX IntelliMAX® Software Suite delivers extraordinary power and performance while remaining intuitive and user friendly, all with an advanced Windows® controller featuring a large 23″ (584 mm) screen for easy viewing of part files and tool paths

The mobile workstation allows easy positioning of the control station, while the bridge allows operation in extreme conditions and integration of air/electric controls for high reliability and simplified maintenance.

Optional accessories such as the A-Jet® for 5-axis cutting and taper compensation, rapid water level control for submerged cutting, and collision sensing terrain follower for machining irregular surfaces expand your jetmachining capabilities and dramatically improve production.

The MAXIEM line of abrasive waterjet machining centers meet a wide range of needs and incorporate proven technologies capable of providing a cost effective, affordable and highly productive solution to users. Configured for your business with broad accessory compatibility, MAXIEM built by OMAX is manufactured entirely in the United States.

Spark & Co. has been a distributor of OMAX waterjet cutting systems (PROTOMAX®, GLOBALMAX®, MAXIEM® and OMAX® series) for over a decade. No one is better equipped to meet your needs in waterjet, Laser (2D laser, Tube Laser, Shaping and Finishing.

For more information: https://www.omax.com/maxiem-waterjet/1515

MAXIEM 1530

MAXIEM 1530 OMAX 2652

OMAX 2652 OMAX 55100

OMAX 55100 Maxiem 1515

Maxiem 1515 Protomax

Protomax