Menu

WP_Post Object

(

[ID] => 2523

[post_author] => 41

[post_date] => 2018-10-04 19:07:50

[post_date_gmt] => 2018-10-04 23:07:50

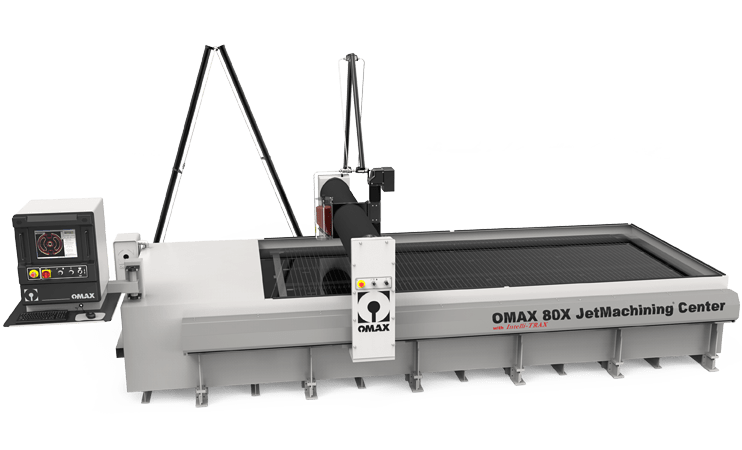

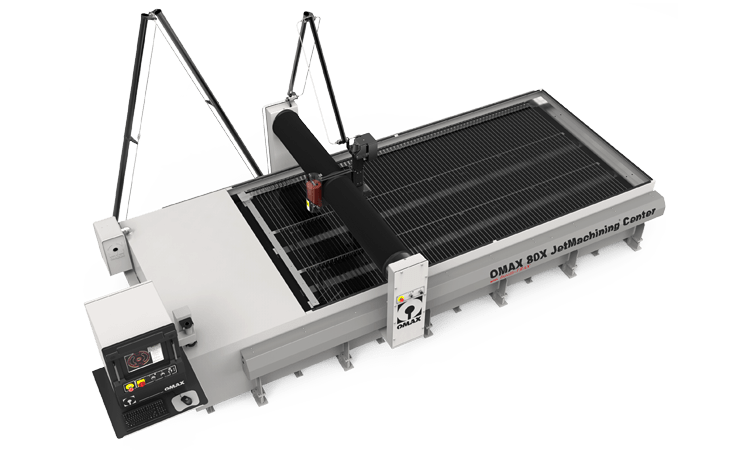

[post_content] => The Omax Waterjet 80X Cutting Machine Series is a robust and reliable abrasive waterjet system available in several length variants designed for your specific needs.

An innovative bridge-style waterjet cutter, the 80X is ideal for cutting larger or multiple part projects in a variety of materials and thicknesses, from metals and composites to glass and plastics and more. It employs the innovative patented Intelli-TRAX® linear drive technology designed exclusively for the abrasive waterjet environment, ensuring superior accuracy and high durability for greater productivity and profitability.

With an X-Y cutting envelope of 13’ 4” x 6’ 8” (4,064 mm x 2,032 mm) a maximum cutting speed of 180 inches per minute (4,572 mm/min) and a linear positioning accuracy of +0.0010” (±0.0254 mm), this bridge-style waterjet machine maximizes profitability through operational efficiency.

The Omax Waterjet 80X cutting machine system comes standard with a host of high-performance features, including a 600lb bulk abrasive delivery system that transports garnet from the assembly's large hopper into the Z-Axis zero-downtime hopper and a rapid water level control for cleaner, safer, and quieter submerged cutting below 80 dBA.

The Omax Waterjet 80X cutting machine series includes a whole lot of Nos: No heat-affected zones or mechanical stresses; No tool changes and minimal fixturing which reduces setup by 50% or more; No additional water required for pump cooling; and No noxious gases, liquid and oils used in, or caused by, the machining process. All of these Nos are a reason to say Yes to this machine!

High efficiency Generation 4 EnduroMAX® pump systems available up to 100 hp deliver the highest nozzle horsepower in the industry while offering operating efficiencies up to 85% to keep production high and energy costs low.

This robust and reliable system can run for 1,000 hours between maintenance to maximize both machine time and profit margins.

Spark & Co. has been a distributor of OMAX waterjet cutting systems (PROTOMAX®, GLOBALMAX®, MAXIEM® and OMAX® series) for over a decade. No one is better equipped to meet your needs in waterjet, Laser (2D laser & 3D laser, Tube Laser, EDM (EDM Sinker, Wire EDM, EDM Drill,) Milling, Shaping and Finishing.

For more information : https://www.omax.com/omax-waterjet/80x-series

[post_title] => OMAX 80X

[post_excerpt] => The Omax Waterjet 80X Cutting Machine Series is a robust and reliable abrasive waterjet system available in several length variants designed for your specific needs.

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => omax-80x

[to_ping] =>

[pinged] =>

[post_modified] => 2022-09-15 13:49:17

[post_modified_gmt] => 2022-09-15 17:49:17

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://spark-co.com/machines/omax-80x/

[menu_order] => 195

[post_type] => machine

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

Array

(

[0] => Waterjet Cutting

)

The Omax Waterjet 80X Cutting Machine Series is a robust and reliable abrasive waterjet system available in several length variants designed for your specific needs.

NOTE: The technical specifications listed below are for the OMAX 80X. See the model comparison for details on the other machines in the series.

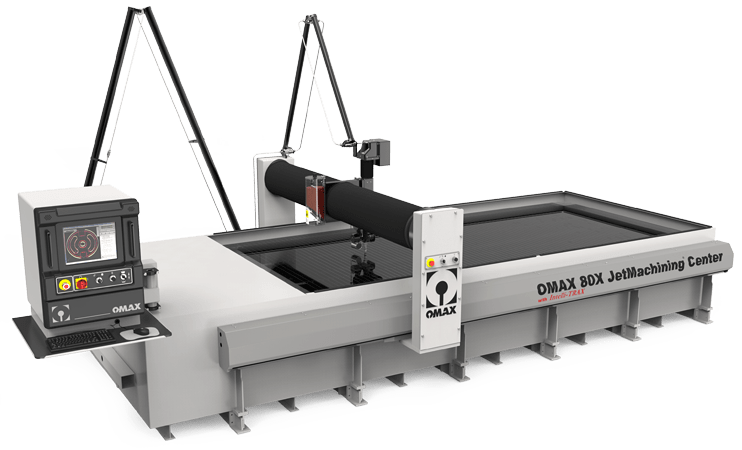

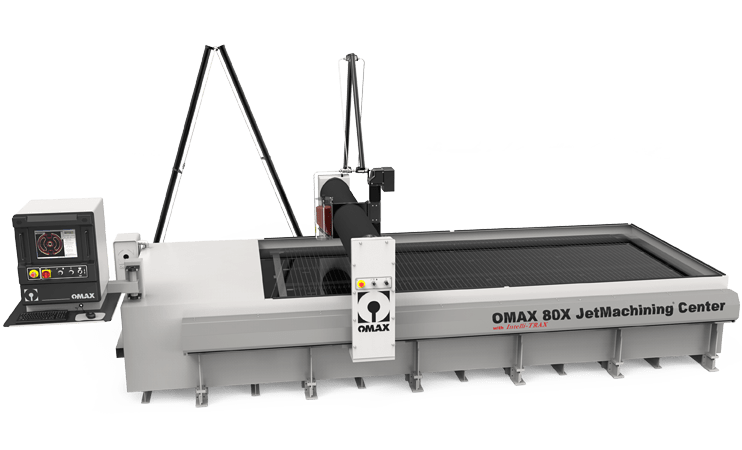

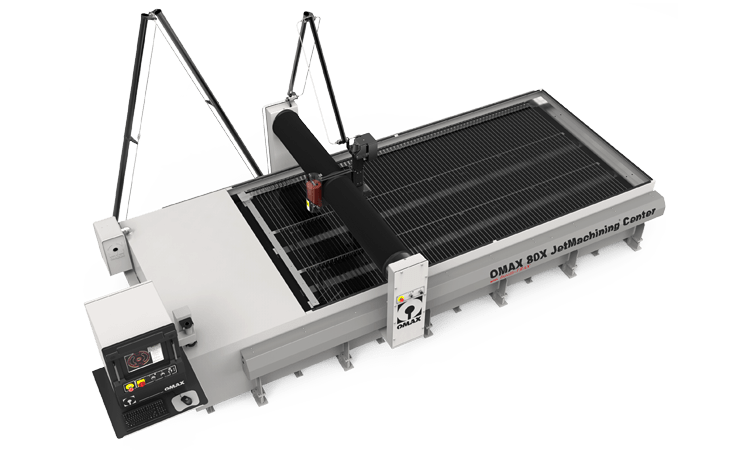

The Omax Waterjet 80X Cutting Machine Series is a robust and reliable abrasive waterjet system available in several length variants designed for your specific needs.

An innovative bridge-style waterjet cutter, the 80X is ideal for cutting larger or multiple part projects in a variety of materials and thicknesses, from metals and composites to glass and plastics and more. It employs the innovative patented Intelli-TRAX® linear drive technology designed exclusively for the abrasive waterjet environment, ensuring superior accuracy and high durability for greater productivity and profitability.

With an X-Y cutting envelope of 13’ 4” x 6’ 8” (4,064 mm x 2,032 mm) a maximum cutting speed of 180 inches per minute (4,572 mm/min) and a linear positioning accuracy of +0.0010” (±0.0254 mm), this bridge-style waterjet machine maximizes profitability through operational efficiency.The Omax Waterjet 80X cutting machine system comes standard with a host of high-performance features, including a 600lb bulk abrasive delivery system that transports garnet from the assembly’s large hopper into the Z-Axis zero-downtime hopper and a rapid water level control for cleaner, safer, and quieter submerged cutting below 80 dBA.

The Omax Waterjet 80X cutting machine series includes a whole lot of Nos: No heat-affected zones or mechanical stresses; No tool changes and minimal fixturing which reduces setup by 50% or more; No additional water required for pump cooling; and No noxious gases, liquid and oils used in, or caused by, the machining process. All of these Nos are a reason to say Yes to this machine!

High efficiency Generation 4 EnduroMAX® pump systems available up to 100 hp deliver the highest nozzle horsepower in the industry while offering operating efficiencies up to 85% to keep production high and energy costs low.

This robust and reliable system can run for 1,000 hours between maintenance to maximize both machine time and profit margins.

Spark & Co. has been a distributor of OMAX waterjet cutting systems (PROTOMAX®, GLOBALMAX®, MAXIEM® and OMAX® series) for over a decade. No one is better equipped to meet your needs in waterjet, Laser (2D laser & 3D laser, Tube Laser, EDM (EDM Sinker, Wire EDM, EDM Drill,) Milling, Shaping and Finishing.

For more information : https://www.omax.com/omax-waterjet/80x-series