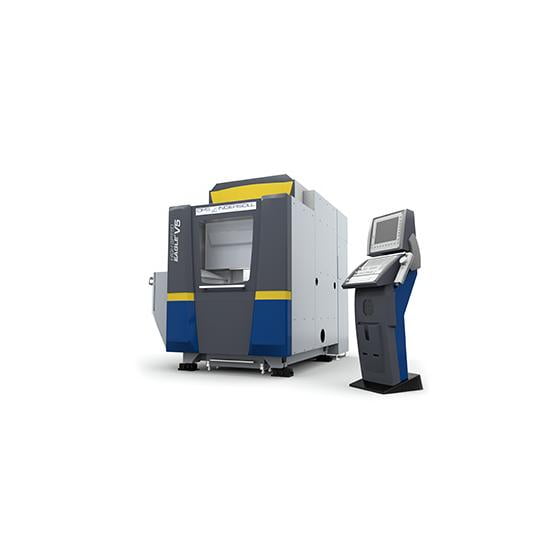

The Eagle V5 is designed to be an ultra-rigid 5-axis vertical machining center with the capacity to handle a 550-pound workpiece on a 15.75-inch table surface.The Eagle V5 gantry-type 5-axis machining center is equipped with a 42,000 RPM integrated spindle, heavy-duty, linear roller guideways and a Dual Gantry Drive, the Eagle V5 is ideal for inclined surface, spiral contour, irregular contour and other complex machining tasks. Includes a Heidenhain iTNC-530 control unit and a side opening for robot loading from either side with pallets up to 15.7-inch square.

Eagle V5 (5-Axis)

Specifications

Machine Travels X x Y x Z: in (mm)

21.6 x 15.7 x 15.7 (550 x 400 x 400)

B-Axis Tilt Range (degree)

-120 ~ 60 degrees

C-Axis Rotation Range (degree)

360 degrees

Spindle Speed

42,000 RPM

Max Rotary Table Cap: dia. x height/lb. (mm/kg)

15.7 x 14.9 / 550 (400 x 380 / 250)

Spindle HP (cont./30 min)

20 HP (15 kw)

Spindle Nose to Table: in (mm)

2.0 ~ 17.7 (50 ~ 450)

Tool Changer Selection

HSK-E40 (32 pos std) / (100 pos optional)

Max Workpiece 3-Axis / in/lb. (mm/kg)

X 21.6 x Y 15.7 x Z 15.7 / 1102 ( 550 x 400 x 400 / 500)

Machine Weight: lb. (kg)

15,873 (7,200)

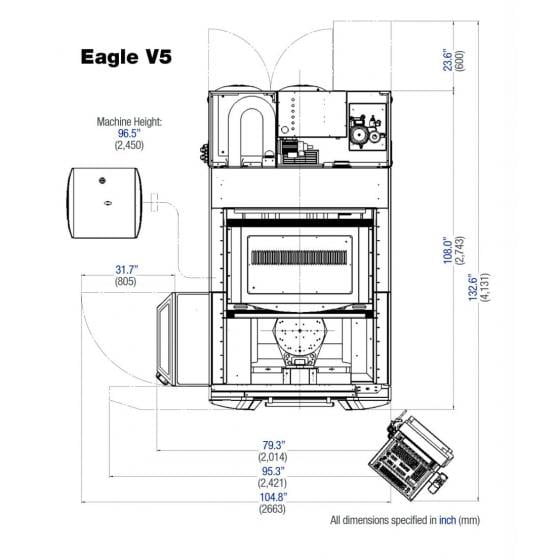

Mach Dimensions W-D-H: in (mm)

79.5 x 110.2 x 96.5 (2,020 x 2,800 x 2,450)

Overview/Features

FEATURES

- ntegrated 4/5-Axis System (without T-slot table)

- Travels: X, Y and Z: 21.6” x 15.7” x 15.7”

- Rapid Traverse: – 1181 in/min (X, Y and Z)

- Max Acceleration: 49ft/s²

- HF Spindle 20hp, 42,000 RPM, HSK-E40 and 32 pos ATC (100 optional)

- Renishaw Infrared Measuring Probe

- Blum Laser System for tool breakage detection and tool length/diameter compensation

- Vibration Dampening Polymer Concrete Machine Bed

- Three-Point Foundation Setup/Leveling

- Ball Screws with Direct Drive AC Motors

- Absolute Measuring with Glass Scales

- Oil Mist Lubricant System, spindle external

- Three-Color Status Light

- Chip Auger with Transverse Conveyor Screw

- Chip Bucket

- Heidenhain iTNC-530 HSCi 5-Axis Simultaneous Control

- Precision Package Three for 5-axis machines: Temperature-distribution compensation, incl.

- ATDC – Automatic Temperature Drift Control

- 5-Axis Compensation

- HEIDENHAIN option Kinematics Opt

- Ceramic Ball for Kinematics accord

OPTIONAL ACCESSORIES

- 100 position ATC

- Table Clamping and Pallet Systems from EROWA, Hirschmann and System 3R

- ICS 2 ATS Internal coolant supply with aerosol dry lubrication

- T-Slot table to cover the 4/5-axis (Converts the machine to 3-axis operation)

- Keller Exhaust System for Graphite and Mist Collection

- Oil mist suction unit

- Chip conveyor for dry milling (incl: chip bucket)

- MultiChange Easy Basic Unit (incl: gripper, 40-pos or 5-pos or 4-pos magazine, workpiece change place and connection to machine)

Plan/Layout