Easy to operate and highly powerful, laser tube cutting solutions from Han’s Laser lead the industry in speed, accuracy, reliability and cost savings. Han’s Laser is a foremost developer and manufacturer of high-performance industrial machines designed to meet the specific needs of a variety of industries.

Sold worldwide, Han’s Laser products are used in multiple industries, including railway communication, automotive applications, mechanical engineering, elevators, agricultural machines, petroleum production as well as packaging and sheet metal processing. Its vast portfolio includes 2D fiber laser and 3D fiber laser cutting solutions, press brakes, laser welding systems, automation, laser tube cutting, and surface treatment innovations.

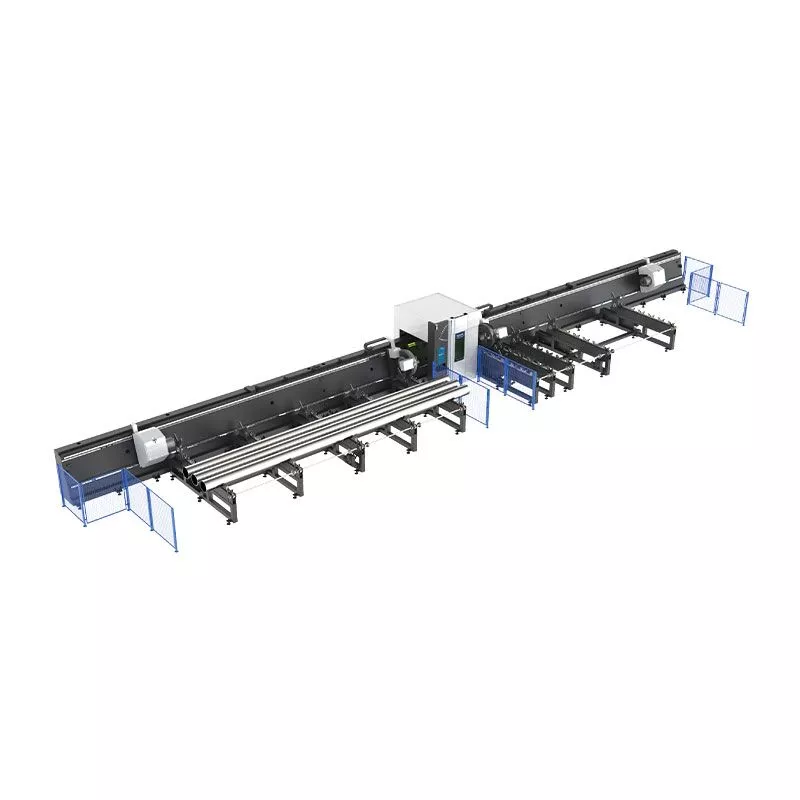

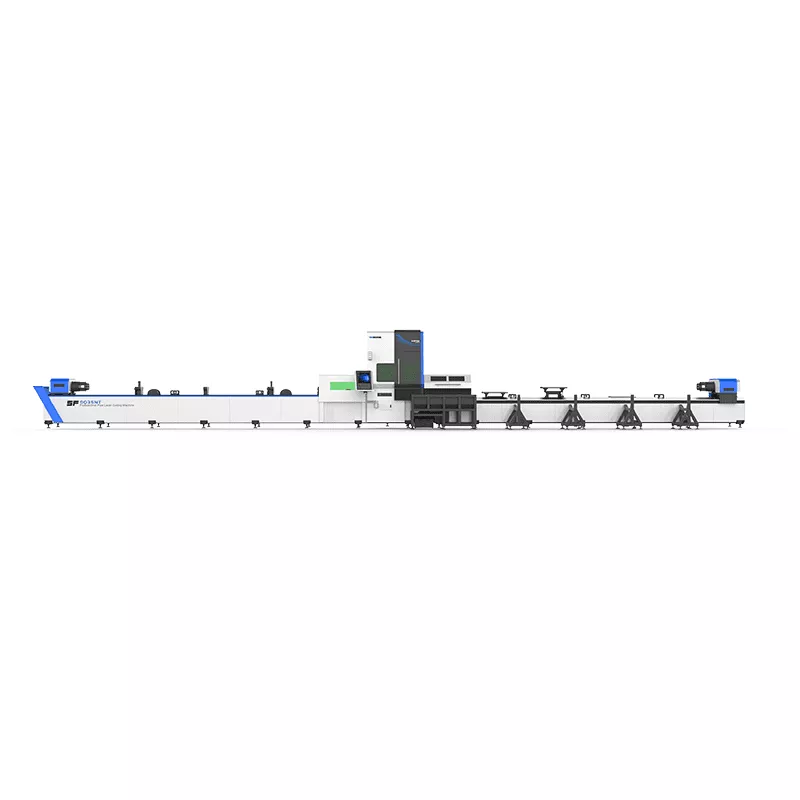

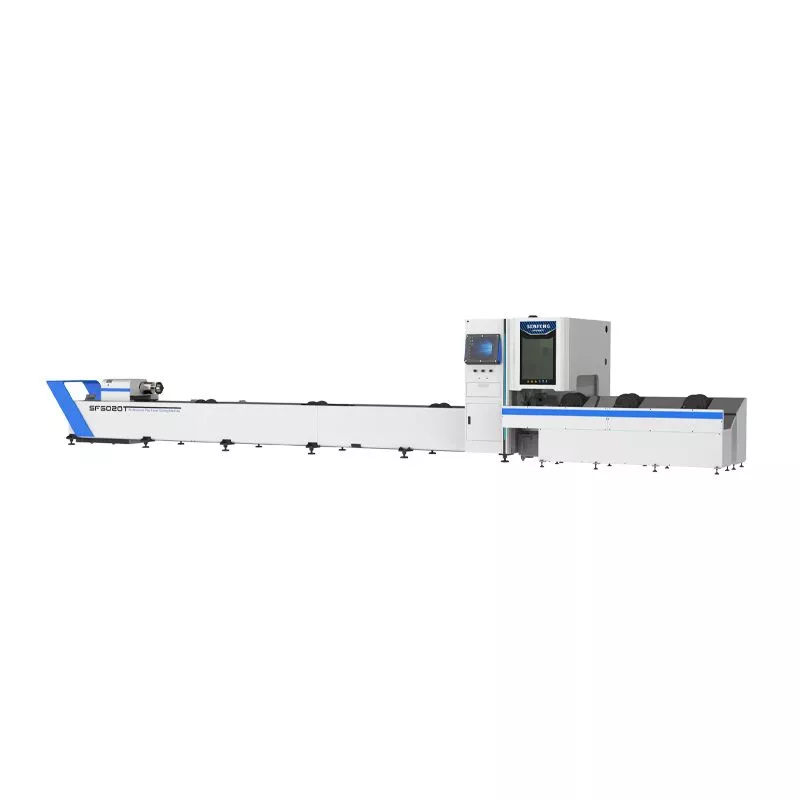

Han’s world-class tube laser cutting systems offer powerful machining capacity, flexibility and excellent performance. Modular in design, these fully-automated cutters can be adapted to suit any application and tube profile, from small to large diameter, specialized shapes and more.

LASER TUBE CUTTING TECHNOLOGY

Laser tube cutting machines, also known as tube laser cutting machines, can cut long pieces of tube or cut holes into sections of tube with incredible precision. Common industries that utilize tube laser cutting include agriculture, architecture, fast food, and construction.

A laser tube cutting machine does it all: material handling, cutting, machining, drilling, tapping, and punching, allowing you to optimize processing and maximize efficiency. Bundle loaders, the most efficient of the tube material handling options, feed one tube at a time from the bundle into the tube laser via a singularizing system.

Laser tube cutting machines are specifically designed to cut a large range of mill-length tube and pipe, whether round, square, rectangular, or triangular. Some of the more advanced options can process I- and H-beams, C-channel, angle iron, and other user-defined shapes.

A high-powered light source is channeled and amplified through fiber-optic cable to be adjusted and focused for the type of material to be cut. Clean, quiet and virtually maintenance-free, fiber laser tube cutting is an economical and effective choice.

When it comes to part quality, proper support for the raw stick can make all the difference. The more chucks on a system, the greater the accuracy will be when the tube is rotating. The ability to support tubing on both sides of the cut is important because inaccuracies can occur if the tube is hanging and unsupported. The addition of a third or fourth chuck allows for removal of a finished part from the cutting area while the first and second chucks are cutting, boosting output.

FIBER LASER VS ABRASIVE WATERJET CUTTING

While these two technologies may be complementary in some ways, there are some clear differences. For example, laser is better for cutting thin metal very precisely and quickly (offering an excellent quality of edge, especially for fine features and holes), while waterjet excels at cutting a wider range of materials with no distortion or heat-affected zone.

Laser cutting is an energy-efficient thermal process, while waterjet employs a cold, supersonic abrasive to cut material, meaning that it doesn’t apply any heat to the material during the process. As a result, abrasive waterjet cutting does not alter the physical state of the material being cut or cause the material to warp from the heat. As waterjets produce such clean cuts, there is minimal finishing required around the edges, resulting in reduced labour and machine time.

Fiber laser cutting is a clean, eco-friendly process, using less energy and producing next to no waste. The small amount of dust produced can be cleaned up quickly and easily with a vacuum or filtering process. Waterjet, on the other hand, requires special disposal of the abrasive waste, which increases operating costs.

While both technologies produce high precision parts, fiber laser cutting offers a higher degree of accuracy for complex part geometries, unattended operation and low operating costs. To this, add high energy efficiency, clean operations, safe processing of highly reflective materials, continuous cutting and higher speeds when cutting thin materials with a single set-up.

WHY BUY HAN’S LASER?

A global bestseller, the P series fiber laser cutting machines from Han’s Laser set the industry standard for precision, productivity and price. Every machine is strictly labeled by ISO9001, ISO14001, GMC Global Excellent Manufacturer Certification, International Standard Labeling Product Certification and CE Certification.

Increase productivity and reduce labour costs with the Han’s Laser patented, push-type high precision, fully-automatic loading and unloading system designed to load bundles of tubes automatically through the laser machine without pipe palletizing.

Go ahead and pile it on: the Han’s Laser P series handles more for less, outclassing the competition when it comes to maximum loading weight.

Another advantage of Han’s Laser P-series laser tube solutions is the incredible machining capacity. Featuring good rigidity, lightweight and dynamic performance, these tube laser cutting systems are built for long-lasting performance.

What’s more, Han’s Laser produces and machines all core parts (champs, drive backplates and all other functional parts except the laser head) with its world-class machining centre. When you buy a Han’s Laser fiber laser tube cutting machine, you know you are getting the best in quality and performance.

Han’s Laser Smart Equipment Group is the global branded integrator for fully automatic laser cutting and welding solutions.

Spark & Co. offers a complete portfolio of Han’s Laser products, including 2D laser (F and HF series), 3D laser (W Series), laser tube cutting (P series), laser welding, automation and surface treatment. Always cutting edges and not corners, no one is better equipped than Spark & Co. to meet your needs in waterjet, 2D laser, 3D laser, EDM (sinker, wire and drill), milling, shaping and finishing.